As a professional manufacturer dedicated to galvanized steel strip production, our factory takes pride in its cutting-edge hot-dip galvanizing production lines and a strict quality control system that covers every stage—from raw material preparation to post-treatment. We adhere to rigorous standards throughout the process, ensuring that every roll of product meets the highest industry requirements.

We prioritize the source of quality by exclusively selecting

high-grade hot-rolled or cold-rolled steel strip as raw materials. This strict material selection lays a solid foundation for the superior initial performance of our galvanized steel strips, eliminating potential quality risks from the start.

Our core hot-dip galvanizing process is backed by sophisticated technology, enabling precise control over three key parameters: zinc pot temperature, steel strip running speed, and zinc liquid composition. This precision results in a uniform zinc coating (40-120 μ m in thickness) that boasts exceptional adhesion and strong corrosion resistance—effectively extending the service life of the steel strips in various harsh environments.

After galvanizing, the steel strips undergo professional post-processing using advanced equipment, including cooling, straightening, and edge cutting/slitting. These steps ensure the final products feature outstanding flatness, straightness, and cutting accuracy, meeting the strict dimensional requirements of different application scenarios.

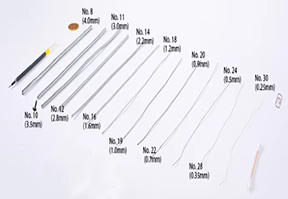

To further guarantee quality, we’ve established a full-range quality inspection system. Using tools like magnetic thickness gauges and conducting tests (bending test, scratch test, salt spray test, etc.), we comprehensively verify the zinc coating’s thickness, adhesion, corrosion resistance, and the product’s overall appearance. Only qualified products (100% pass rate) are delivered to customers.

Beyond standardized products, we offer tailored galvanized steel strip solutions to address the unique needs of customers in diverse industries, including building materials, automotive manufacturing, home appliances, and agriculture & animal husbandry. Our professional packaging and logistics team provides high-quality packaging services, ensuring products remain intact during transportation—solving customers’ worries about damage in transit.

With consistent product reliability, advanced technology, and efficient customer service, we have earned long-term trust and recognition from clients across sectors. We are committed to continuing as a reliable partner for all your galvanized steel strip needs.