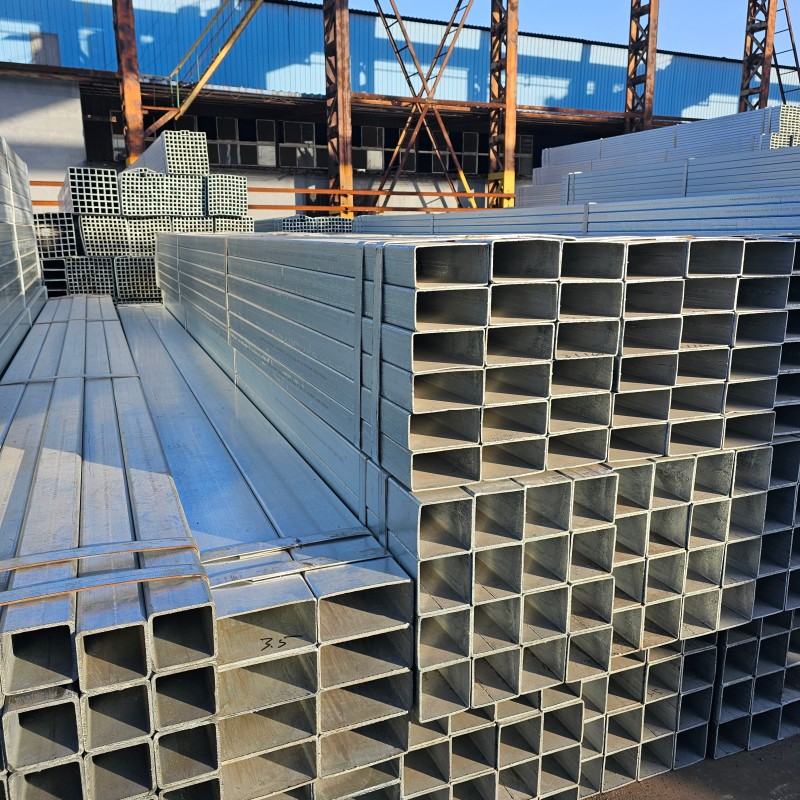

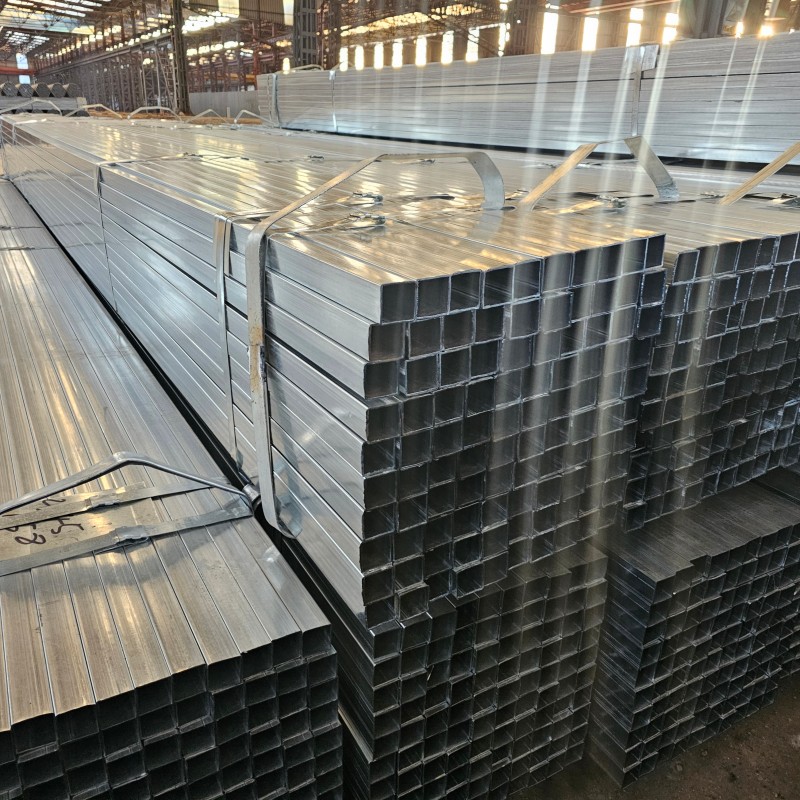

Top Quality Hot Dipped Galvanized Rectangular Square Steel for Outdoor Structures

description1

Production description

Product Name |

Galvanized Rectangular Steel Pipe |

Shape |

square, rectangle |

Size |

square:15 - 200mm, rectangle wide: 20 - 100mm, rectangle long: 30 - 200mm |

Thickness |

0.6 - 6mm, or customer's requirement |

Length |

6m or According To Customer's Demands |

Grade |

Q195, Q235B, Q355B |

Standard |

ASTM, DIN, JIS, BS, GB/T, EN |

Galvanized layer thickness |

Pre galvanized steel pipe: 10 - 40g/m² |

Hot dip galvanized steel pipe: 200 - 600g/m² |

Production process

Raw Material Preparation

Select high-quality carbon steel coil plates or strips as raw materials, and conduct strict inspections on their specifications, materials, etc., to ensure compliance with production standards.

Production Process

Square Steel Pipe Forming

Unroll the prepared carbon steel coil plates or strips through an uncoiler, and then send them to a leveling machine for leveling treatment to eliminate the bending and waviness of the plates. Next, use a forming machine to curl the leveled plates into round steel pipes, and firmly weld the seams by means of high-frequency welding or other welding methods. Then, pass the round steel pipes through a sizing machine to extrude them into square steel pipes of the required size. Finally, cut the square steel pipes according to the required length.

Production Process

Hot-dip Galvanizing Treatment

First, pickle the formed square steel pipes to remove impurities such as rust and oil stains on the surface, and then put them into a flux solution to enhance the bonding force between the zinc layer and the surface of the steel pipes. After that, immerse the square steel pipes in molten zinc at a temperature of approximately 450 - 480°C for a certain period of time to form a uniform and dense layer of zinc-iron alloy and pure zinc on the surface of the steel pipes. After the galvanizing is completed, take the square steel pipes out of the zinc liquid, and conduct cooling and passivation treatment to improve the corrosion resistance of the galvanized layer. Finally, conduct quality inspection and surface cleaning of the galvanized square steel pipes.

Production Application

Footwear abrasion solutions

1. Construction Field: Used as building structure frames, scaffolding, balcony guardrails, stair handrails, and materials for lightweight building structures, etc.

2. Mechanical Manufacturing Field: Applied to manufacture mechanical parts, components of conveying equipment, frames of agricultural machinery, etc.

3. Automotive Industry Field: Used to construct automobile chassis, seat frames, and some parts of the vehicle body frame and doors, etc.

4. Power Engineering Field: Serve as supports for power equipment and cable trays, and are used in the supporting structures of new energy power generation equipment.

5. Agricultural Field: Used to build frames of agricultural greenhouses, supports and pipelines of irrigation systems, fences for livestock and poultry farming, and supporting structures of livestock and poultry houses.

6. Home Decoration Field: Used to make furniture frames, indoor partitions and screens, and outdoor furniture.

7. Municipal Engineering Field: Used as road guardrails, pipelines and supports of drainage systems, and lamp posts and lamp frames in urban lighting projects.