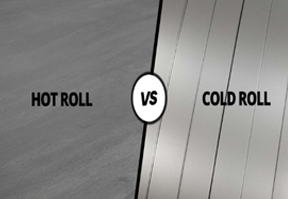

What's the difference between hot rolled and cold rolled steel?

In the fields of industrial production and construction, steel is widely used as a basic material, and cold-rolled steel and hot-rolled steel play important roles in various scenarios due to their different performance characteristics. The core difference between the two lies in the different production processes, which directly determine their significant differences in performance, appearance, and application.

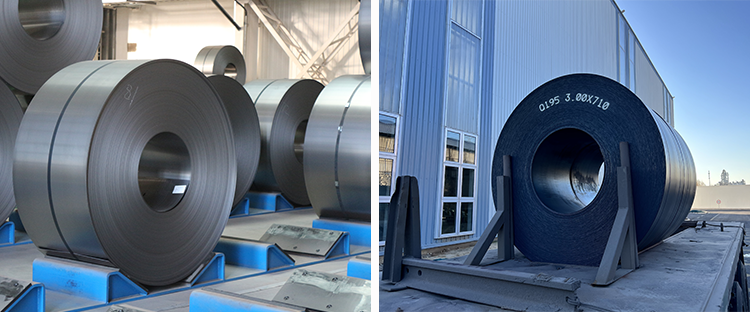

From the perspective of production technology, hot-Rolled Steel is a type of steel that is heated to high temperatures (usually exceeding 1000 ℃, reaching the austenitizing temperature of the steel) and then rolled into shape through rolling equipment. At high temperatures, steel has better plasticity and is more easily processed into various shapes, such as steel plates, steel sections, steel pipes, etc. After rolling, it can be naturally cooled. Cold rolled steel is further processed by rolling semi-finished products (such as hot-rolled coils) made from hot-rolled steel at room temperature. Due to rolling at low temperatures, the deformation resistance of steel is relatively high, requiring the use of more precise equipment and greater rolling force. The rolling process may also be accompanied by annealing, acid washing, and other processes to adjust the performance and surface quality of the steel.

The differences in production processes directly lead to significant differences in performance and appearance between the two. In terms of performance, hot-rolled steel has coarse grains and an uneven internal structure, resulting in relatively low strength and hardness. However, it has good plasticity and toughness, making it easy to perform cutting, welding, bending, and other processing operations. Its mechanical properties are greatly affected by temperature, and there may be some internal stress during the natural cooling process after high-temperature rolling. Cold rolled steel undergoes multiple rounds of rolling at room temperature, resulting in finer grains and denser internal structure. Its strength and hardness are significantly improved, especially in terms of yield strength and tensile strength, which far exceed those of hot-rolled steel. However, its plasticity and toughness decrease, making it relatively difficult to process. At the same time, the dimensional accuracy of cold-rolled steel is higher, and the thickness deviation can usually be controlled within ± 0.01mm, while the dimensional accuracy of hot-rolled steel is lower, and the thickness deviation is generally around ± 0.1mm.

In terms of appearance, hot-rolled steel forms a layer of iron oxide scale on the surface after high-temperature rolling, which is mostly black brown or blue black in color, with a rough surface and poor hand feel. If the appearance needs to be improved, subsequent treatments such as rust removal and painting are required. Cold rolled steel undergoes acid washing to remove surface oxide scale before rolling. After rolling, the surface is smooth and clean, presenting the silver bright color of the metal itself. It can be used directly without excessive treatment and is more suitable for scenarios with high requirements for appearance.

Based on the differences in performance and appearance, cold-rolled steel and hot-rolled steel each have unique advantages and correspond to different application scenarios.

The core advantages of hot-rolled steel are good plasticity, ease of processing, and relatively low production costs. Due to the lack of complex cooling and subsequent processing techniques during the rolling process, the production efficiency is high and suitable for large-scale production. In terms of application scenarios, hot-rolled steel is widely used in the field of building structures, such as making steel beams, columns, hot-rolled steel bars, etc. for steel structure factories. With its good toughness and load-bearing capacity, it meets the mechanical requirements of building structures; In mechanical manufacturing, hot-rolled steel is often used as raw materials for machine tool beds, mechanical equipment bases, etc., which can be further processed through cutting, casting, and other processes; In addition, hot-rolled steel is also used in the field of pipeline transportation, such as steel pipes for oil and gas pipelines, as well as preliminary formed parts for automobile frames.

The advantages of cold-rolled steel are reflected in high hardness, high strength, high precision, and excellent surface quality. Its dense internal structure GIves it excellent load-bearing capacity and deformation resistance, while precise size control and smooth surface reduce subsequent processing steps. In application scenarios, cold-rolled steel is an important material in the field of automobile manufacturing, commonly used to make components such as car body shells, doors, engine hoods, etc. It not only meets the strength requirements of the car body, but also ensures a smooth and beautiful appearance; In the manufacturing of household appliances, cold-rolled steel is used for the outer shell and inner liner of refrigerators and washing machines, as well as the heat sink of air conditioners. With its good surface quality and corrosion resistance (some cold-rolled steel is galvanized), it enhances the texture and service life of household appliances; In addition, cold-rolled steel is also used in precision instrument manufacturing, electronic equipment casings and components, as well as lightweight and high-precision fields such as cans and metal packaging.

In summary, cold-rolled steel and hot-rolled steel are not superior or inferior, but are adapted to different application needs based on the characteristics formed by production processes. In actual production selection, it is necessary to combine the project's requirements for material strength, processing difficulty, appearance quality, and cost budget, and reasonably choose cold-rolled steel or hot-rolled steel to achieve the optimal match between material performance and application scenarios.