0102030405

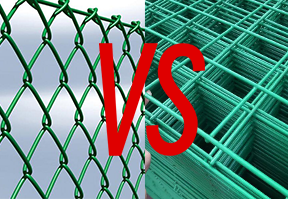

Welded vs Woven Wire Mesh Fences: How to Choose (Design & Application Guide)

2025-09-26

When it comes to securing spaces, enhancing landscapes, or defining boundaries, Wire Mesh Fences stand out as versatile solutions—but choosing betweenWelded wire mesh fence and Woven Wire Mesh fence requires careful consideration of design goals and real-world use cases. Both options excel in different scenarios, and understanding their unique traits, along with factors like Wire mesh Fence Sizes, Mesh Wire Fence price, and wire mesh fence details, is key to making an informed decision.

Core Differences: Welded vs. Woven Wire Mesh

At the heart of the choice lies the manufacturing process, which shapes each fence’s strength, flexibility, and aesthetic appeal.

Welded wire mesh—often crafted as Welded steel wire meshfor added durability—is made by fusing intersecting wire strands at their joints. This creates riGId, uniform grids that maintain their shape even under pressure. The result iswire mesh fence panels that feel sturdy and structured, ideal for applications where stability is non-negotiable. In contrast, Woven Wire Mesh (including Woven Steel Wire Mesh) is constructed by interlacing wires like a textile, producing a flexible, resilient barrier. This weaving process creates a more organic look, with wires that can stretch slightly without breaking—a key advantage in high-impact or dynamic environments.

Design Focus: Matching Fences to Aesthetic Goals

Designers and homeowners increasingly prioritize fences that blend functionality with style, making Wire mesh fence designs and Modern wire fence ideas critical considerations.

Welded Wire Mesh Fences: Clean Lines for Contemporary Spaces

Welded wire mesh fence shines in modern design schemes, thanks to its crisp, uniform grids. The welded joints eliminate the "loose" appearance of woven mesh, creating a sleek, minimalist look that complements urban homes, commercial buildings, or modern gardens. These fences are highly customizable in terms of Wire mesh Fence Sizes—grids can range from small (1/4-inch) for security to large (4-inch) for decorative purposes—and wire mesh fence details like powder-coated finishes (in black, gray, or even bold hues) add a polished touch. For example, a black Welded Steel wire mesh fence paired with wooden posts can frame a backyard patio without blocking natural light, aligning with modern "open-concept" outdoor design trends. Another example is its use in urban rooftop gardens: 2x2-inch grid Welded wire mesh fence panels with a matte white finish create a safety barrier around planter beds while maintaining the space’s airy, contemporary vibe, fitting perfectly with Modern wire fence ideas that prioritize both form and function.

Woven Wire Mesh Fences: Texture and Tradition

Woven Wire Mesh fence, including the popular Chain Link Fence (a type of woven mesh), offers more texture and visual depth, making it a favorite for traditional or rustic settings. The interlaced wires create a pattern that softens the fence’s appearance, making it suitable for residential neighborhoods, farms, or parks where a harsh, industrial look is unwanted. Woven Wire Mesh also provides more design flexibility in terms of wire thickness and weave pattern—for instance, a tight-weave Woven Steel Wire Mesh fence can serve as a privacy screen when paired with climbing plants (like ivy or jasmine) in a suburban front yard, while a loose-weave design works for decorative garden borders around a cottage-style home. Unlike welded mesh, woven fences can be adjusted slightly to follow uneven terrain, such as the sloped yard of a rural cabin, adding to their natural, organic appeal. A classic use case is a galvanized Chain Link Fence with a green vinyl coating around a 1950s-style bungalow; the textured weave complements the home’s traditional architecture without clashing with existing landscaping.

Application Scenarios: Functionality First

Beyond design, the intended use case is the most important factor in choosing between welded and woven wire mesh fences.

When to Choose Welded Wire Mesh Fences

- Security-Centric Spaces: The rigid structure of Welded wire mesh makes it difficult to cut or bend, making it ideal for securing yards, commercial properties, or industrial sites. For example, a manufacturing facility that stores expensive equipment might install 1/2-inch grid Welded Steel wire mesh fence panels around its perimeter—this small grid prevents trespassers from squeezing through and deters theft attempts. Small-grid welded mesh is also perfect for pet enclosures: a backyard dog run for a small breed like a Chihuahua could use 1x1-inch Welded wire mesh fence to keep the pet safely contained while blocking rodents from entering the space.

- Flat Terrain Installations: Welded mesh panels are best suited for level ground, as their rigidity makes them hard to adapt to slopes. They’re easy to install in straight lines, making them a top choice for urban lots or rectangular gardens. A prime example is a city apartment complex with a rectangular courtyard: 6-foot-tall Welded wire mesh fence panels (4x8 feet in size) create a uniform boundary around the space, separating the courtyard from the street while maintaining visibility. Another use is around a community vegetable garden in a park—flat ground allows for quick installation of welded mesh panels, and the rigid structure keeps the fence upright even when gardeners lean against it while tending to plots.

- Low-Maintenance Needs: Welded joints are less prone to wear and tear than woven wires, and Welded wire mesh fence requires minimal upkeep—just occasional cleaning to remove dirt or rust. This makes it a practical option for busy homeowners or commercial properties. For instance, a restaurant with an outdoor dining patio might choose a black powder-coated Welded Steel wire mesh fence; the finish resists weather damage, and staff only need to wipe down the panels once a month to keep them looking clean. A school playground is another ideal spot: welded mesh fences can withstand frequent contact with children’s play equipment (like swings or slides) without fraying, and the low maintenance means the school doesn’t need to allocate extra funds for regular repairs.

When to Choose Woven Wire Mesh Fences

- Dynamic or Uneven Environments: Woven Wire Mesh (including Chain Link Fence) is flexible, allowing it to contour to hills, dips, or curved boundaries. This makes it perfect for rural properties, farms, or areas with rocky terrain. A sheep farm in a hilly region, for example, might use Woven Steel Wire Mesh fences to enclose grazing pastures—the flexible mesh follows the natural slope of the land, ensuring no gaps where sheep could escape. A homeowner with a backyard that has a small creek and uneven ground could install a Chain Link Fence around the property; the woven mesh bends slightly to fit around tree roots and small mounds, creating a seamless boundary without the need for extensive ground leveling.

- High-Impact Areas: Woven mesh’s ability to stretch slightly makes it more resistant to damage from strong winds, falling branches, or animal collisions. Farmers often use Woven Steel Wire Mesh fences to contain livestock, as the flexible wires can absorb the impact of cows or horses without breaking. A horse stable, for instance, might line its paddocks with 4-foot-tall woven mesh—if a horse leans against the fence, the wires give slightly instead of snapping, reducing the risk of injury to the animal and damage to the fence. In coastal areas prone to hurricanes, Chain Link Fence is a popular choice for residential properties; the woven design can withstand high winds (up to 100 mph in some cases) without collapsing, unlike rigid welded mesh which might crack under pressure.

- Cost-Effective Large-Scale Projects: Mesh Wire Fence price is often lower for woven options like Chain Link Fence, especially for large areas (like acreages or sports fields). Woven mesh also requires fewer materials to cover space, making it a budget-friendly choice for expansive properties. A local park and recreation department, for example, might install Chain Link Fence around a 10-acre soccer complex—at 25 per linear foot, the total cost is significantly lower than using welded mesh, allowing the department to allocate funds to other park improvements (like new goalposts or seating). A homeowner with a 5-acre rural lot could use Woven Wire Mesh to divide the property into sections for gardening, livestock, and a backyard—rolls of woven mesh (50 feet long) are easy to unroll and install over large distances, cutting down on both material and labor costs.

Practical Considerations: Size, Price, and Details

To finalize your choice, factor in Wire mesh Fence Sizes, Mesh Wire Fence price, and wire mesh fence details:

- Sizes: Welded mesh is typically sold in pre-cut wire mesh fence panels (4x8 feet is common), while woven mesh (like Chain Link Fence) is often available in rolls (50-100 feet long) for custom sizing. Choose smaller grids (1-2 inches) for security and larger grids (3-4 inches) for decorative use. For example, a welded mesh fence around a tool shed might use 1x1-inch grids to prevent theft, while a decorative woven mesh fence around a flower bed could use 3x3-inch grids to let sunlight through.

- Price: Welded wire mesh fence is generally more expensive than Woven Wire Mesh fence due to the welding process. For example, Welded Steel wire mesh panels can cost 40 per panel, while Chain Link Fence rolls start at 25 per linear foot. However, welded mesh’s durability may reduce long-term replacement costs. A homeowner who plans to live in their home for 20+ years might opt for welded mesh—even though the upfront cost is higher, they won’t need to replace the fence as often as a woven mesh option, which might start to fray after 10-15 years.

- Details: Pay attention to wire mesh fence details like wire gauge (thicker wires = more strength), material (steel for durability, aluminum for rust resistance), and finishes (powder coating for longevity). Welded mesh may require additional bracing for large panels, while woven mesh often needs tensioning to stay taut. For a coastal home, an aluminum Woven Wire Mesh fence with a marine-grade finish is a smart choice—it resists saltwater corrosion, unlike steel which might rust. For a commercial warehouse, 10-gauge Welded Steel wire mesh panels (thicker than the standard 12-gauge) with extra bracing at the corners can withstand heavy impacts from forklifts or delivery trucks.

Final Verdict: Align Fence Type with Goals

For modern, sleek designs on flat terrain where security and rigidity are key—such as urban patios, manufacturing facilities, or school playgrounds—Welded wire mesh fence (especially Welded Steel wire mesh) is the best choice. For traditional, textured looks on uneven ground or budget-friendly large-scale projects—like rural farms, coastal homes, or soccer complexes—Woven Wire Mesh fence (including Chain Link Fence) is the way to go. By balancing Wire mesh fence designs, application needs (from pet enclosures to hurricane-prone areas), and practical factors like Wire mesh Fence Sizes and Mesh Wire Fence price, you can select a fence that enhances both the function and beauty of your space.