Optimize Projects with Galvanized & Black Annealed Wire

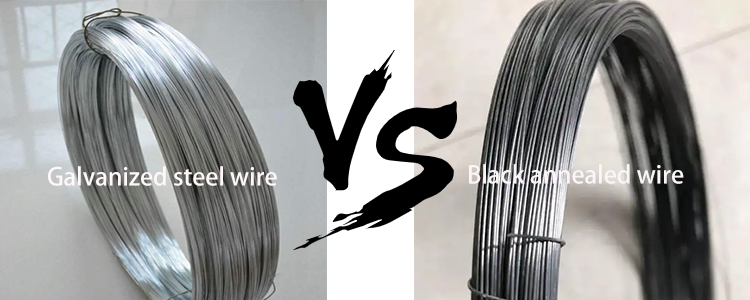

Choosing the right Metal Wire makes the project worry free and efficient!Galvanized steel wire and black annealed wire, accurately matching different needs

In wire procurement, selecting the right category often doubles project efficiency and improves costs. Galvanized Wire and annealed wire, as the two mainstream products, belong to the category of metal wire, but have clear differences in performance and applicable scenarios, helping you quickly find the right solution!

To pursue long-term durability and corrosion resistance, choose galvanized wire! It forms a zinc layer on the surface of iron wire through hot-dip galvanizing or electroplating processes, like putting a layer of "protective clothing" on the Steel Wire, so that the galvanized wire can withstand outdoor exposure for 3 years without fading, and is not easy to rust in humid environments. Even when used in coastal areas, it can effectively prevent corrosion. At the same time, galvanized wire retains high strength characteristics, with a tensile strength of 300-500MPa, and is not easily broken after bending for more than 5 times. Its load-bearing and impact resistance capabilities far exceed ordinary iron wire, and its service life is 3-5 times that of ordinary iron wire, reducing maintenance and replacement costs from the source.

If we focus on flexibility, ease of processing, and fine operation, annealed wire is a better solution! After high-temperature annealing process, the internal stress of the iron wire is fully released, and the material becomes soft and easy to shape. It can be easily bent into rings, waves, etc. by hand, and there is no risk of cracking during cutting. The weaving efficiency is increased by more than 40% compared to ordinary iron wire. Moreover, the surface of the annealed wire is finely polished, smooth and free of burrs, which will not scratch the hands of operators during processing, and can also avoid damaGIng gift packaging paper, precision parts surfaces, etc., ensuring processing safety and product quality.

In terms of application scenarios, the division of labor between the two is clear: galvanized wire, with its strong anti-corrosion and high tensile advantages, is widely used for outdoor fence construction (farm and factory protection), greenhouse skeleton fixation, fishing net weaving, steel bar binding in municipal engineering, and outdoor facility reinforcement in coastal areas; Annealed wire, due to its flexibility and ease of processing, is used in crafts weaving (wire lanterns, metal ornaments), gift packaging bundling (gift box decorative ropes), electronic component fixing (precision part protection), and daily hardware processing (small metal mesh) scenarios.

Whether you need to deal with harsh outdoor environments or pursue fine processing effects, choosing the right galvanized wire or annealed wire can improve both project quality and efficiency, meeting the needs of different scenarios!