High quality galvanized steel strip: analysis of core characteristics and comprehensive overview of diverse application scenarios

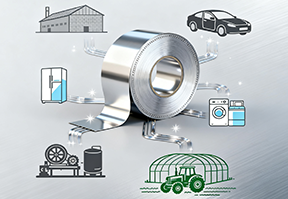

Jinxuan Steel's high-quality galvanized steel strip has become a popular product in the steel market due to its outstanding advantages in material and performance. This product meets the needs of multiple industries and provides efficient and reliable raw material solutions for fields such as automotive, construction, home appliances, and loGIstics.

1、 Product core features: high-quality presentation from material to performance

Galvanized Steel strip has the core advantages of high corrosion resistance, easy processing, and strong stability. Through mature processes and material optimization, it meets the strict requirements of industrial production for basic materials

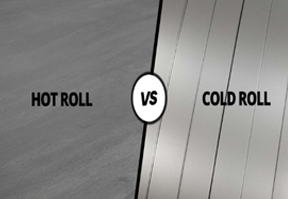

1. Super corrosion resistance: The product adopts hot-dip galvanizing process and has been tested by the National Steel Product Quality Supervision and Inspection Center. The product has a corrosion resistance time of over 1500 hours in neutral salt spray test, far exceeding the industry average of 800 hours. Even in coastal high salt spray, industrial high pollution and other environments, it can still achieve a service life of more than 15 years, greatly reducing the maintenance cost of downstream products.

2. Excellent processability: In response to various processing needs such as stamping, bending, and welding in industrial production, low-Carbon Steel substrates are selected, with an elongation rate increased to over 35% and a bending angle of up to 180 ° without cracking. The surface roughness of the steel strip is controlled below Ra0.8 μ m to ensure even opening and closing of the welding points and no porosity during welding; At the same time, the adhesion of the zinc layer reaches the highest level in the GB/T 2518-2019 standard. After stamping, the zinc layer does not peel off or expose the bottom, perfectly adapting to high-precision component processing, and increasing the production pass rate of downstream enterprises to over 99.5%.

3. Stable physical performance: The product undergoes strict quality control, with tensile strength controlled between 300-500MPa, flatness error ≤ 2mm/m, and thickness deviation controlled within ± 0.02mm and width deviation ± 0.5mm. It can be directly put into production without secondary cutting, improving processing efficiency.

2、 Diversified application scenarios: "universal materials" covering multiple industries

Galvanized steel strip, with its flexible adaptability, has achieved mature applications in four core areas and become a key material for promoting industry production upgrading:

1. In the field of automobile manufacturing: dual guarantee of lightweight and safety

In automobile manufacturing, this product is mainly used for body structural components, chassis components, and interior frames:

The structural components such as the body side panels and door inner panels are made of galvanized steel strips with a thickness of 1.2-1.8mm. With high tensile strength and corrosion resistance, the body weight is reduced (by 10% compared to traditional cold-rolled steel) while improving its collision resistance and service life;

The brackets, crossbeams, and other components of the chassis suspension system are made of products with a zinc layer thickness of 200g/㎡ or more, which can resist the erosion of road mud, water, and salt, and prevent component corrosion and fracture;

The dashboard bracket and seat rails in the interior utilize the excellent processability of the product to achieve precise molding of complex shapes and reduce assembly errors.

At present, the product has reached cooperation with multiple mainstream car companies and is applied in the production of various new energy vehicles and fuel vehicles, helping the automotive manufacturing industry achieve the goals of "lightweight, high safety, and long life".

2. In the field of architectural decoration: full scene adaptation for both outdoor and indoor environments

In the construction industry, products can meet the dual needs of outdoor protection and indoor decoration:

In outdoor scenes, galvanized steel strips with a thickness of 0.3-0.8mm are processed by color coating to produce color steel tiles, curtain wall panels, etc., which are used for roofs and exterior walls of factories, warehouses, and steel structure residences. Their corrosion resistance can ensure that the building appearance does not fade or rust significantly for 10 years, and they are easy to install, reducing construction costs by more than 50% compared to traditional tiles and stone materials;

In indoor scenes, thin gauge (0.15-0.3mm) galvanized steel strips can be processed into light steel keels, ceiling brackets, etc. With high flatness and ease of cutting, they are suitable for different types of ceiling and partition installations, and do not emit formaldehyde, meeting green building standards;

In addition, in municipal engineering, this product is also used in the manufacturing of street lamp posts and traffic guardrails. With the dual protection of hot-dip galvanizing and spray coating, it can be used for a long time in harsh outdoor environments, reducing municipal maintenance investment.

3. In the field of home appliance production: improving product texture and durability

In home appliance manufacturing, galvanized steel strip is the core material for the shell, inner liner, and structural support

The outer shell of refrigerators and washing machines is made of galvanized steel strip with a thickness of 0.5-0.8mm. After stamping and spraying, the surface is smooth and flat, not easy to scratch or rust, and has excellent heat dissipation performance, which can extend the service life of household appliances;

The evaporator bracket of the indoor air conditioning unit and the fan cover of the outdoor unit are made of products with a zinc layer thickness of 120g/㎡, which can resist the risk of corrosion caused by changes in indoor and outdoor humidity and avoid component failure;

The inner lining of kitchen appliances such as microwave ovens and ovens is made of high temperature resistant galvanized steel strip (specially passivated), which can withstand high temperatures above 200 ℃ and is easy to clean without rusting, enhancing the user experience of household appliances.

At present, this product has entered the supply chain of several leading electric appliance companies and is applied to more than ten types of home appliances such as refrigerators, washing machines, and air conditioners, helping home appliance companies improve product quality and market competitiveness.

4. Logistics and warehousing field: efficient solutions for shelves and packaging

In the logistics and warehousing industry, this product is mainly used for storage shelves and transportation packaging:

The load-bearing components of the storage shelves, such as columns and beams, are made of galvanized steel strips with a thickness of 2.0-3.0mm. With high tensile strength and stability, they can withstand a load of 500-2000kg per layer and have strong corrosion resistance, making them suitable for long-term use in damp environments in warehouses;

The steel pallets and packaging steel strips used for transportation are made of thin galvanized steel strips, which are lightweight and strong, and can replace wooden pallets and plastic packaging. They not only have stronger load-bearing capacity (30% higher than wooden pallets), but can also be recycled, reducing logistics packaging costs and environmental pressure.

With the rapid development of e-commerce logistics, the demand for this product in the fields of warehousing shelves and logistics packaging continues to grow, becoming an important material for promoting the "cost reduction, efficiency improvement, and green" development of the logistics industry.

3、 Customized Services: Exclusive Solutions Tailored to Industry Needs

To further meet the personalized needs of different industries, Jinxuan Steel also provides customized services: the thickness (0.15-3.0mm), width (15-1500mm), and zinc layer thickness (30-275g/㎡) of the steel strip can be adjusted according to customer needs, and supporting processing services such as passivation, oil coating, slitting, and opening can be provided to reduce customer's subsequent processing steps. At the same time, the enterprise establishes a rapid response mechanism, with regular specification products able to be delivered within 72 hours, and customized product delivery cycles not exceeding 15 days, ensuring that customer production progress is not hindered.

As a fundamental material in the industrial field, high-quality galvanized steel strip is becoming a "booster" for the upgrading and development of multiple industries due to its excellent performance and wide adaptability. In the future, Jinxuan Steel will continue to optimize its products based on market demand, promote the application of galvanized steel strips in more emerging fields, and provide solid support for the high-quality development of the industrial economy.

Keywords: Zinc-coated Steel Coil,Heavy-gauge Galvanized Steel Coil,Electro-galvanized Steel Coil,GSC (Galvanized Steel Coil),Galvanized Coil (Steel),Galvanized Steel Coil,Corrosion-resistant Galvanized Coil,Pre-galvanized Steel Coil,GI,Galvanized Carbon Steel Coil,Hot-dip Galvanized Steel Coil,Galvanized Steel strip,Electro-galvanized Steel strip,Hot-dip Galvanized Steel strip,Heavy-gauge Galvanized Steel strip,GSC (Galvanized Steel strip),Galvanized Carbon Steel strip,Galvanized strip (Steel),Pre-galvanized Steel strip,Corrosion-resistant Galvanized strip,Zinc-coated Steel strip