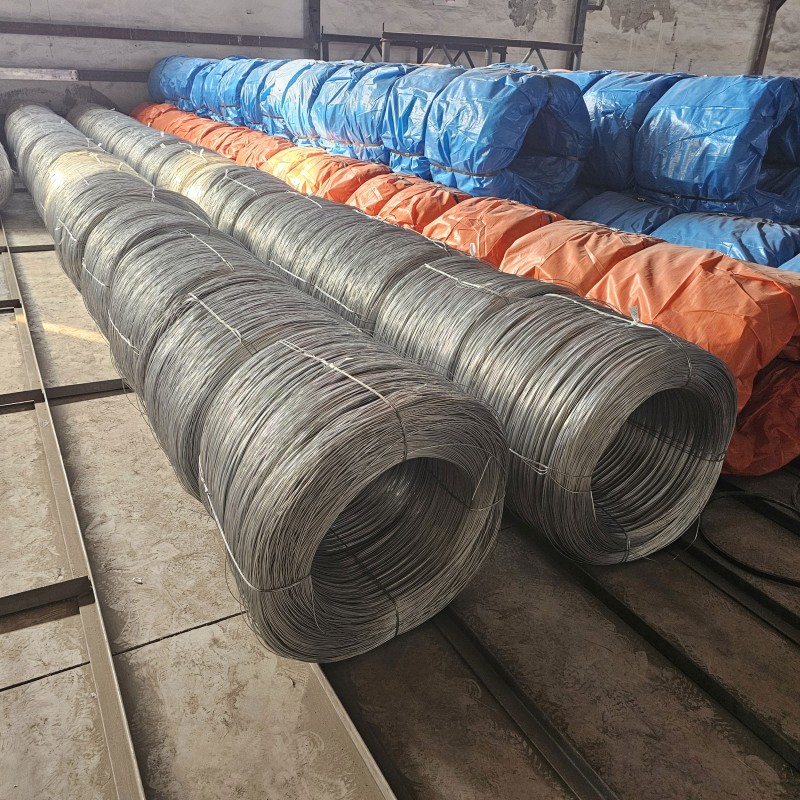

Maintenance High Tensile Strength Galvanized Steel Wire

description1

Production description

Product name |

Galvanized Wire |

Size |

0.15 - 5.0mm or as customer requirements |

Zinc coat |

10 - 200g/m2 or as customer requirements |

Wire weight |

5 - 50kgs/coil or as customer requirements |

Grade |

Q195, Q235B, 45#, 50Mn, 65Mn, 70Mn |

Standard |

ASTM, DIN, JIS, BS, GB/T, EN |

Packing |

Coil with plastic cloth inside and hessian outside or weave outside |

MOQ |

5 tons |

Production process

Raw Material Preparation

The production of galvanized steel wire starts with wire rod as the raw material.

Production Process

Cold Drawn

The wire rod is cold drawn and stretched through a die at room temperature to reduce its diameter and increase its strength. This initial cold - drawing process is crucial for obtaining the desired wire specifications.

Production Process

pickling

After cold drawing, the steel wire is pickled by being immersed in an acid solution to remove impurities such as rust and scale on the surface. This pickling step ensures that the subsequent processes can be carried out smoothly and that the final product has a clean surface.

Production Process

Annealing

Once the pickling is completed, the steel wire undergoes annealing. Through heating, holding at a certain temperature, and slow cooling, the work hardening is eliminated, the plasticity and toughness are restored, and the internal structure is improved. Annealing helps to optimize the mechanical properties of the steel wire.

Production Process

Galvanized

After annealing, the steel wire enters the galvanizing process. A zinc layer is formed on its surface through processes such as hot - dip galvanizing or electroplating to enhance its corrosion resistance. The galvanizing process is what gives the steel wire its characteristic durability and protection against the elements.

Production Process

Finished Product

Finally, the steel wire that has gone through a series of processing steps becomes a finished product, which can be packaged and put into the market for use. From raw material to finished product, each step plays an important role in ensuring the quality and functionality of the galvanized steel wire.

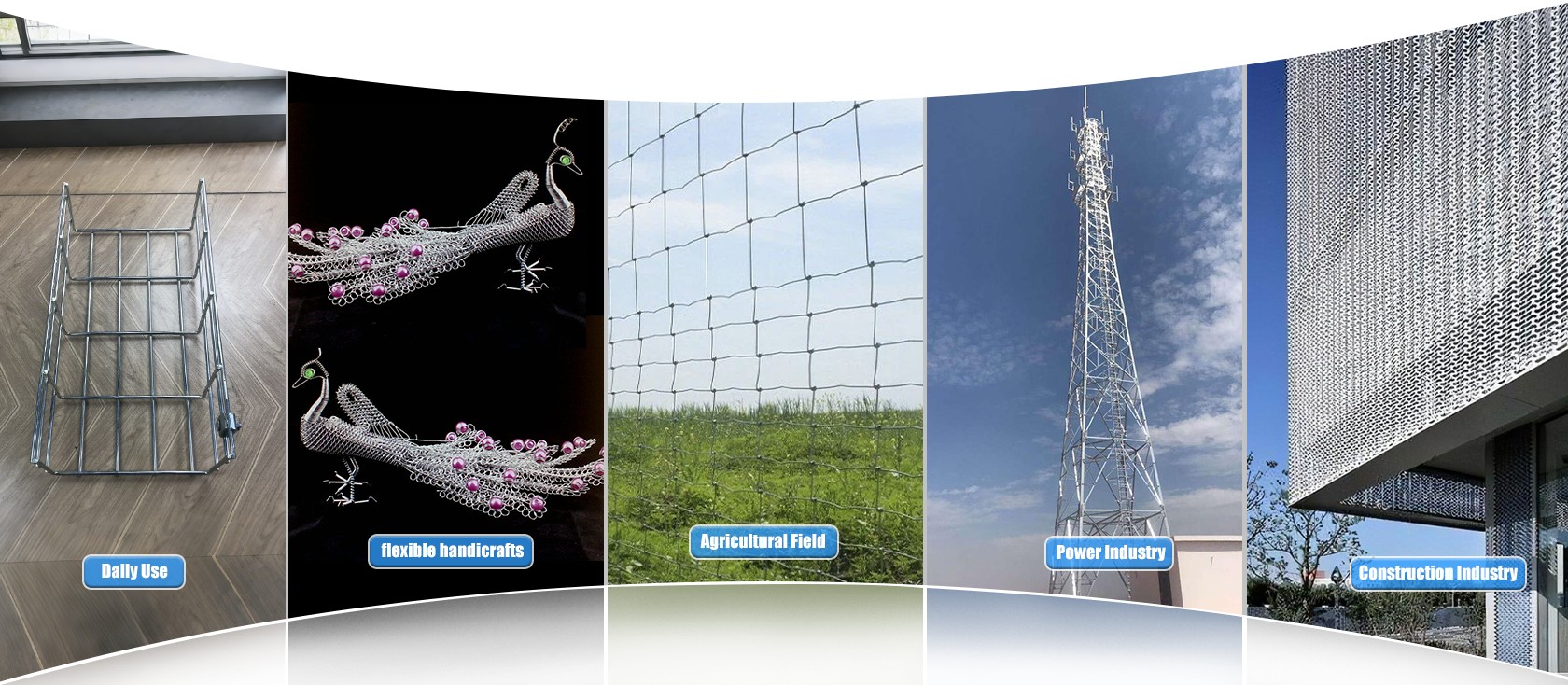

Production Application

Footwear abrasion solutions

Construction Industry

Galvanized steel wire strengthens concrete structures (via meshes), secures wall insulation materials, and creates rust-resistant decorative elements for durable, stable, and aesthetic buildings.

Power Industry

Used in high-strength, corrosion-resistant steel strands for overhead power lines and protective cable trays, ensuring safe, long-lasting electricity transmission and cable protection.

Telecommunications Industry

Forms durable structural components for outdoor communication towers and protective pipes for communication cables, enhancing tower stability and signal quality while resisting environmental damage.

Agricultural Field

Widely applied in rust-proof fences (pasture/orchard), greenhouse framework/film fixation, and agricultural packaging (e.g., basket binding), offering long-life, low-maintenance solutions for farming needs.

Daily Use

Manufactures rust-resistant household items (furniture hardware, racks, rods) and flexible handicrafts (iron art, weavings), combining durability with decorative versatility for everyday applications.