Low prices, high quality, customizable carbon steel wire rods

description1

Production description

Product name |

Wire rod |

Diameter |

6mm-12mm, 6.5mm, 8.0mm, 10.0m or according to customer's requirement |

coil weight |

2 tons or according To Customer's Demends |

Tolerance |

Within 0.2mm |

Grade |

Q195,Q215, Q235, HPB195, HPB215, HPB235, HPB300, SAE1006, SAE1008, SAE1045, SAE1055, SAE1022, 45#,50Mn,65Mn,70Mn, HRB400E, HRB500E, H08A, H08MnA, SWRH62B, SWRH77B, SWRCH35K, SWRCH22A, ER70S-6 |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Technique |

hot rolled |

MOQ |

2 tons |

Production process

Steelmaking

Melt iron ore and scrap steel to produce molten steel.

Production Process

Continuous Casting

Solidify molten steel into billets.

Production Process

Reheating

Heat billets to the right temperature for rolling.

Production Process

Rolling

Use rolling mills to shape billets into wire rods.

Production Process

Cooling

Rapidly cool wire rods to get the right properties.

Production Process

Coiling & Inspection

Coil the wire rods, check quality, and package for shipment.

Production Application

Footwear abrasion solutions

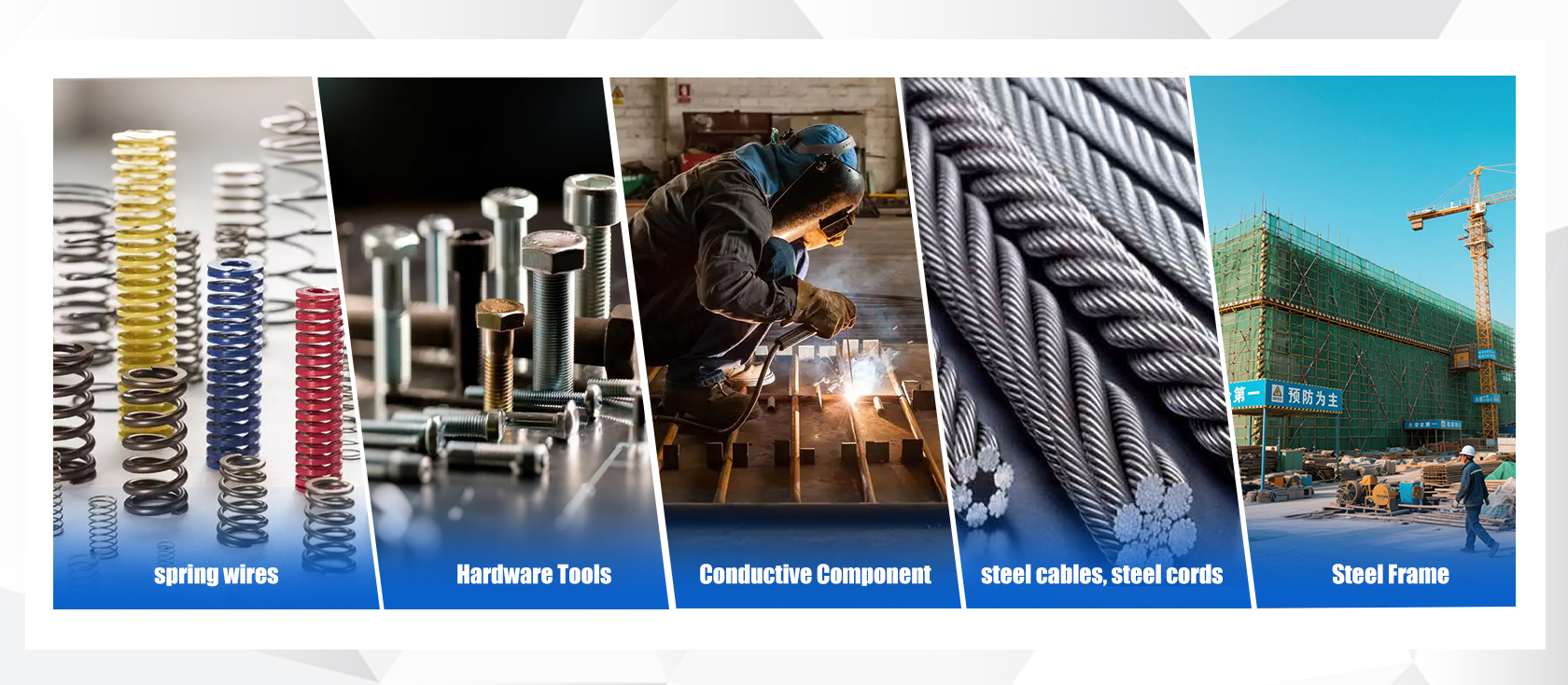

1. Construction: Wire rod is processed into steel reinforcement frames for concrete structures or used as binding materials in engineering projects like houses and bridges.

2. Mechanical Manufacturing: Wire rod can be processed into steel wires, steel cables, spring wires, etc., or serve as raw materials for manufacturing mechanical parts and automotive components.

3. Electronics and Electricity: After drawing and plating treatment, wire rod is made into wires, cables, or conductive components for household appliances, communication equipment, and electrical systems.

4. Hardware Tools: Wire rod acts as a core material for manufacturing electrode cores, tool blanks (such as wrenches and pliers), and basic components of hardware products.

5. Spring Manufacturing: Wire rod is processed into helical springs through cold/hot forming processes, used as shock-absorbing or elastic components in automotive, mechanical, and furniture industries.

6. Bearing Manufacturing: Wire rod is refined and cold-headed into bearing steel balls, serving as key components of rolling bearings.

7. Metal Products: Wire rod is processed into steel cables, steel cords, steel strands, etc., applied in lifting equipment, tire reinforcement materials, and architectural tension structures.