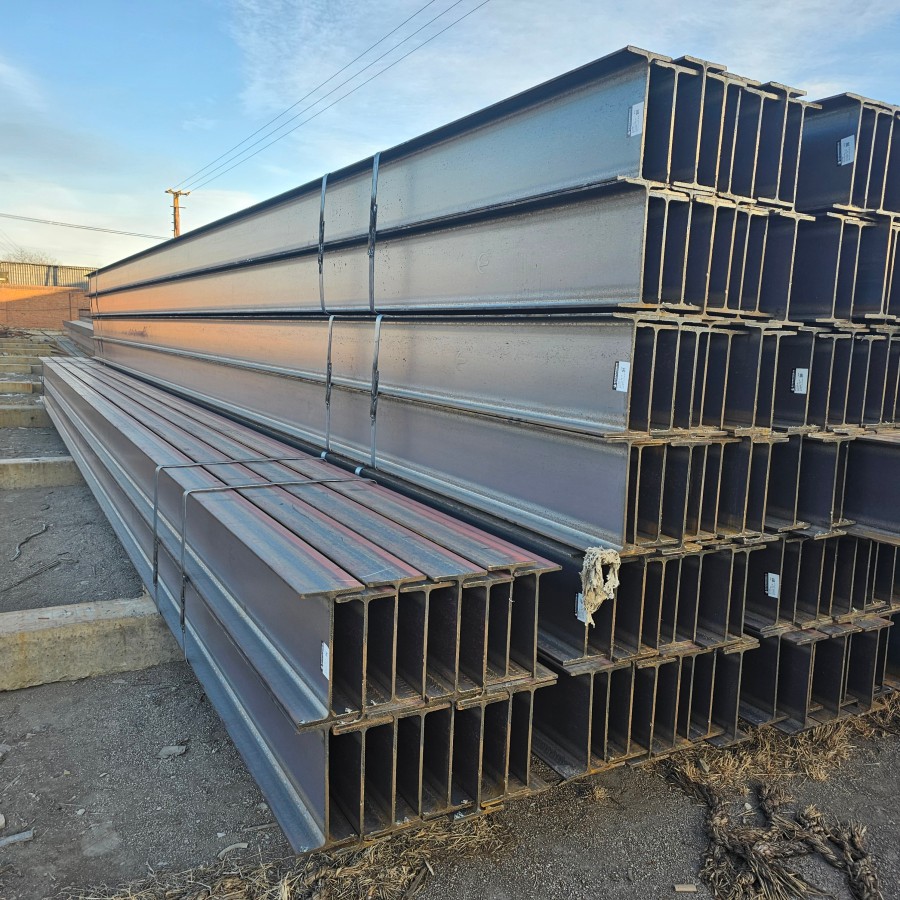

Factory manufacturer supplies low prices various specifications H beams for sale

description1

Production description

Product name |

H beam |

Flange Thicknes |

7-30mm or customize according to customer requirements |

Flange width |

50-300mm or customize according to customer requirements |

Web Thickness |

4.5-30mm or customize according to customer requirements |

Web height |

100-1000mm or customize according to customer requirements |

Steel Grade |

Q235B,Q355B |

Technique |

Hot rolled,welded |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Production process

Raw Material Preparation

Select high-quality continuous casting billets or blooming billets, and control the composition, dimensions, shape, etc.

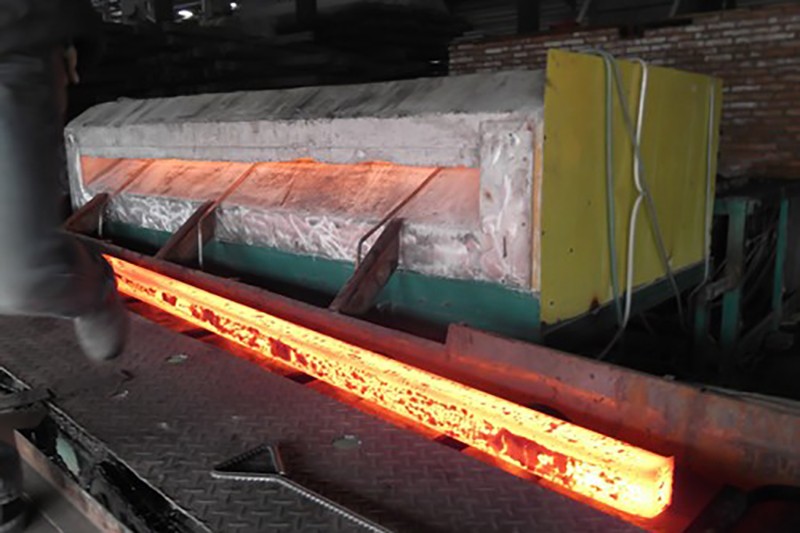

Production Process

Heating

Heat the billets in a heating furnace to a temperature ranging from 1100 to 1250℃.

Production Process

Rolling

First, carry out rough rolling to reduce the cross-sectional size of the billets and make them approximate the shape of H-beam. Then, perform finish rolling to precisely control the dimensions and improve the surface quality.

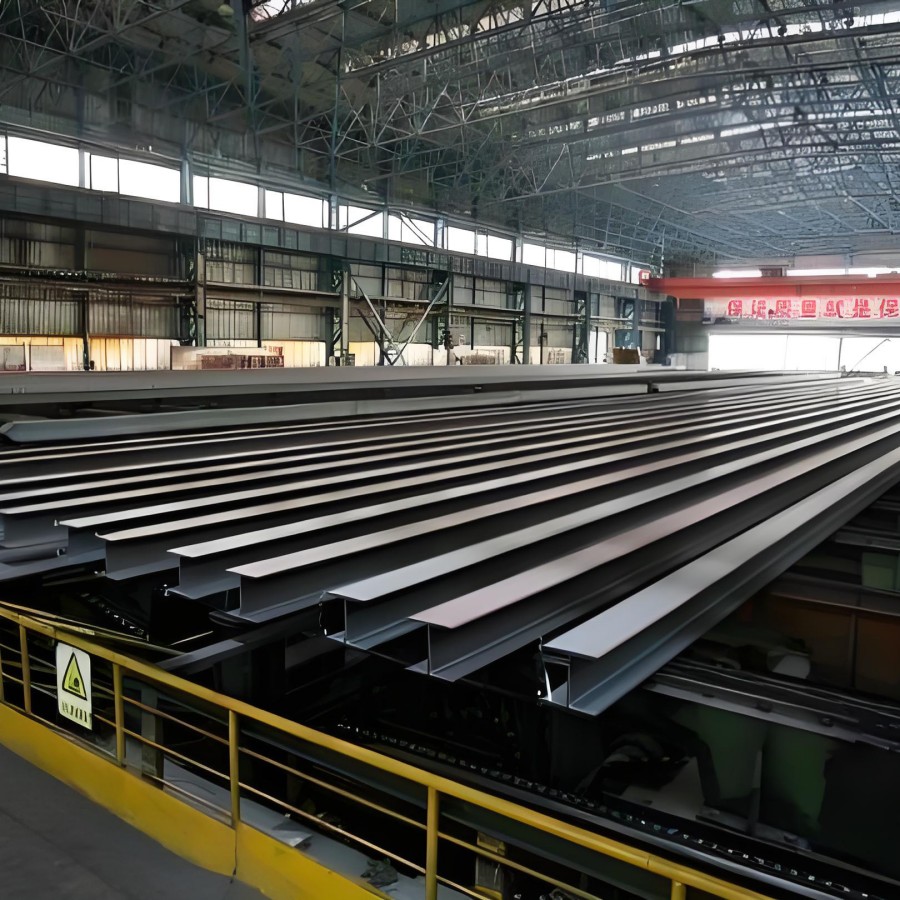

Production Process

Cooling

Use air cooling or water cooling to control the cooling rate and temperature to ensure the organizational performance.

Production Process

Straightening

Use a straightening machine to eliminate the deformation generated during cooling and ensure the straightness and flatness.

Production Process

Inspection

Conduct inspections such as dimensional accuracy inspection, appearance quality inspection, mechanical property inspection, and non-destructive inspection.

Production Process

Finished Product Processing

Mark the product information, package according to the requirements, and then store them in the warehouse or deliver them to customers.

Production Application

Footwear abrasion solutions

● In the construction field: It is used for the roof trusses and crane beams of industrial plants, the beams and columns of the frameworks in high-rise buildings, and the upper structures of bridges, etc.

● In mechanical manufacturing: It is suitable for the frameworks of large-scale equipment and the frames of conveying machinery, ensuring the stable operation and precision of the equipment.

● In other aspects: It is a major material for power transmission towers, and is used for port trestles and lighthouses. It can also serve as the supporting structure for facilities such as agricultural greenhouses and farms.