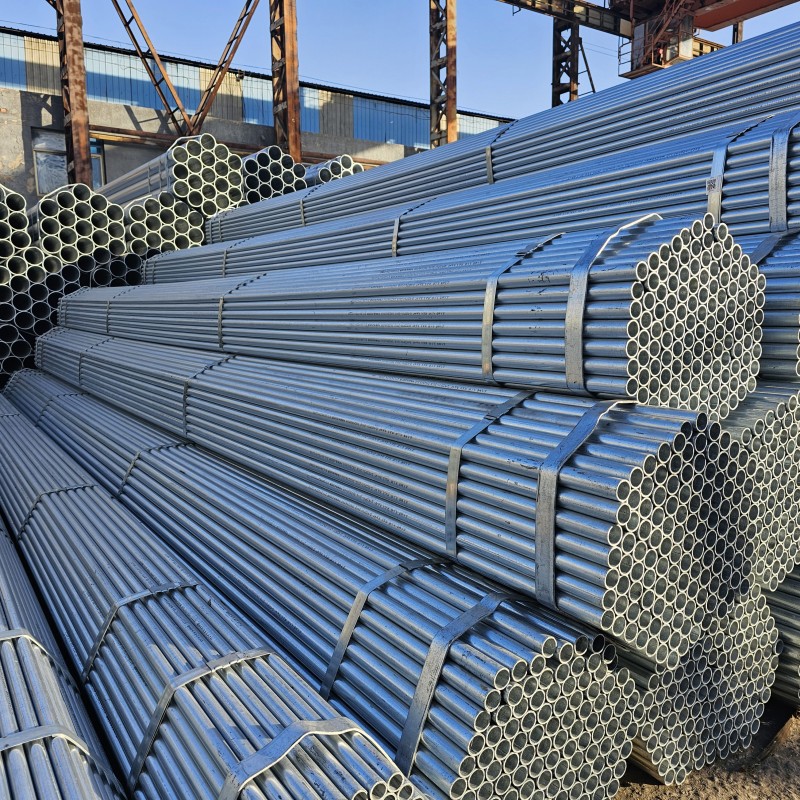

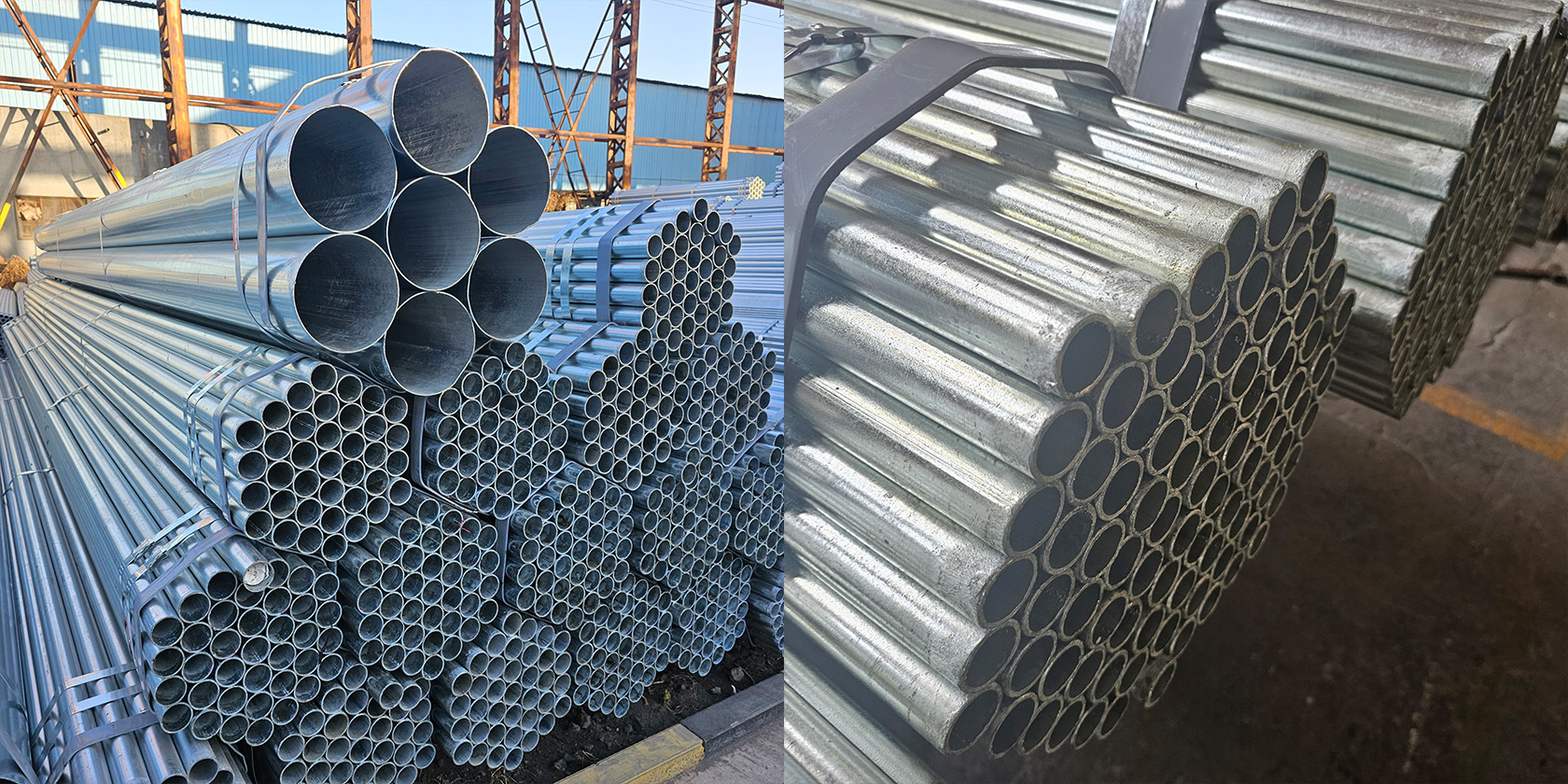

Factory Direct Sale Good Quality Galvanized Steel Round Pipe

description1

Production description

Product Name |

Galvanized round Steel Pipe |

Outer DIA |

15mm-273mm or according to customer's requirement |

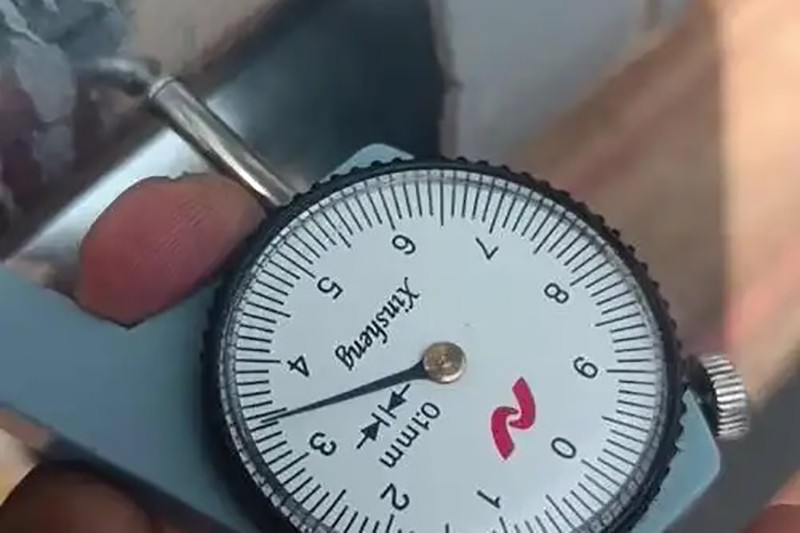

Thickness |

0.5mm-6.0mm or customer's requirement |

Length |

6m or According To Customer's Demends |

Steel Grade |

Q195,Q235B,Q355B |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Galvanized layer thickness |

Pre galvanized steel pipe;10-40g/m2 |

Hot dip galvanized steel pipe;200-600g/m2 |

Production process

Raw Material Preparation

Select high - quality steel coils. Cut and process them into the required round pipe blanks according to specific dimensional requirements.

Production Process

Pipe Forming

Use rolling or welding techniques to process the blanks into round pipes. Welded pipes require precise seam welding, while seamless pipes are formed through hot extrusion or cold extrusion.

Production Process

Surface Treatment

Thoroughly clean the pipes to remove impurities, oil stains, and rust. This step ensures better adhesion of the zinc coating.

Production Process

Galvanization

Immerse the cleaned pipes in molten zinc (hot - dip galvanization) or apply a zinc coating through electroplating. Hot - dip galvanization forms a thick and durable zinc layer, enhancing the corrosion resistance of the pipes.

Production Process

Passivation

Form a passive film on the surface of the galvanized layer through chemical treatment to improve corrosion resistance and weather resistance.

Production Process

Quality Inspection

Strictly inspect the dimensions, surface quality, and corrosion resistance of the pipes. Remove defective products from the production line.

Production Process

Finishing and Packaging

Cut the pipes to the required lengths and then package them properly for storage and transportation.

Production Application

Footwear abrasion solutions

● In the construction field: They are used as scaffolding, structural supports, and water supply and drainage pipes.

● In municipal engineering: Applied to underground drainage, street lamp poles, and greening irrigation.

● In the agricultural field: Serving as the framework of greenhouses and irrigation pipelines, and also used in facilities of livestock farms.

● In the industrial field: Used to build factory workshop supports and act as conveying pipelines, meeting various production requirements.