Exceptional Durability Galvanized Steel Coils for Construction, Automotive & More

description1

Production description

Product name |

Galvanized steel coil |

Width |

100-1250mm, 1000mm, 1219mm, 1250mm, 1500mm or according to customer's requirement |

Thickness |

0.12-2.5mm, 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm or customer's requirement |

Coil weight |

3-10 tons or customer's requirement |

Surface Structure |

Slightly oiled,Galvanized |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Grade |

DC51D+Z,DC52D+Z,DC53D+Z, DX51D+Z, SGCC, SGCD, SGHC, SGH340, DX51D+AZ, DC51D+AZ, DX51D+ZAM, DC51D+ZAM, SECC, DX51D+ZF, DC51D+ZF, CSA, CSB, SS33, S350GD |

Coating Weight |

30-300g/m2 |

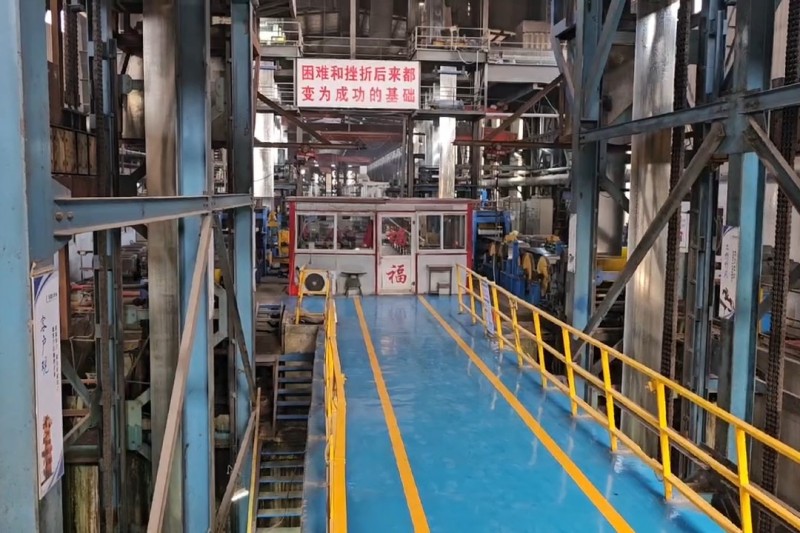

Production process

Raw Material Preparation

Firstly, select high-quality hot-rolled base plates or cold-rolled base plates as production raw materials to lay the foundation for subsequent production.

Production Process

Pickling Treatment

Remove the scale and impurities on the surface of the steel through the pickling process, ensuring that the steel surface is clean and ready for galvanization.

Production Process

Galvanizing Process

Adopt the hot - dip galvanizing or electrogalvanizing process to evenly coat the surface of the steel with a zinc layer, endowing the steel with excellent corrosion resistance.

Production Process

Cooling Stage

Cool the galvanized steel to make the zinc layer stably adhere to the steel surface.

Production Process

Post - treatment Process

Finally, through post - treatment processes such as leveling and passivation, further improve the surface quality and performance of the galvanized coils, thus obtaining the finished galvanized coils.

Production Application

Footwear abrasion solutions

In the construction field: Used for building keels, steel structure frames, roof panels, wall panels, etc., ensuring structural stability and resisting wind and rain erosion.

In the home appliance industry: Used for manufacturing casings of home appliances such as refrigerators and air conditioners, as well as internal components like brackets, combining aesthetics and durability.

In the automotive manufacturing: Applied to vehicle body panels, chassis, and suspension system components, enhancing safety and durability.