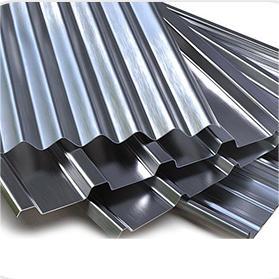

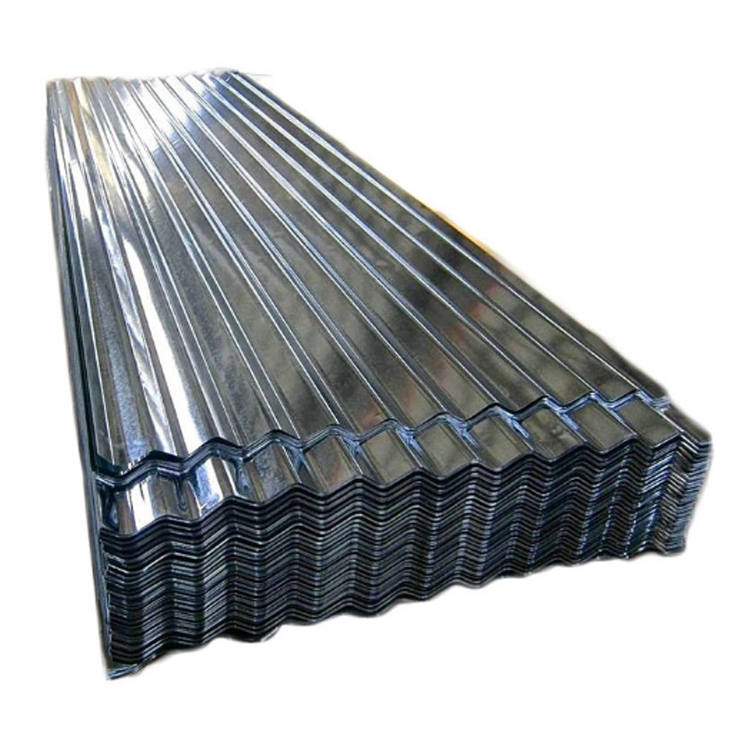

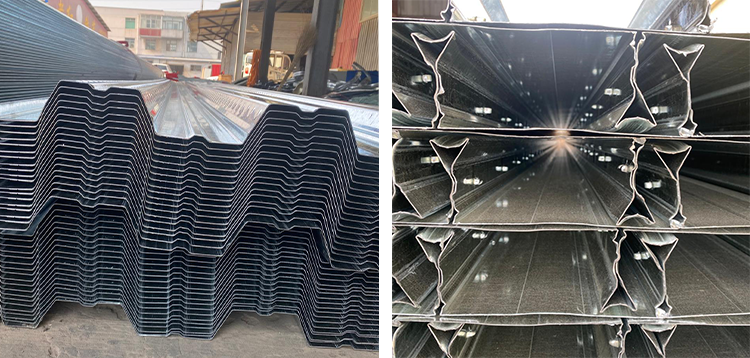

DX51D+Z Galvanized Corrugated Steel Sheet for Walls

description1

Production description

Product Name |

Prepainted Galvanized Corrugated steel Sheet |

Thickness |

0.12 - 1.2mm or According To Customer's Demands |

Width |

700 - 1250mm or as customer's requirement |

Length |

1400 - 6000mm or as customer's requirement |

Zinc coating |

Z20 - 60 or as customer's requirement |

MOQ |

5 tons |

Standard |

ASTM, DIN, JIS, BS, GB/T, EN, ROCT |

Grade |

TDX51D+Z, TDX52D+Z, TDX53D+Z, TDC51D+Z, TDX51D+AZ, TDX51D+ZAM, TDC51D+AZ, TDC51D+ZAM, TSGCC, CCSB, CCSC

|

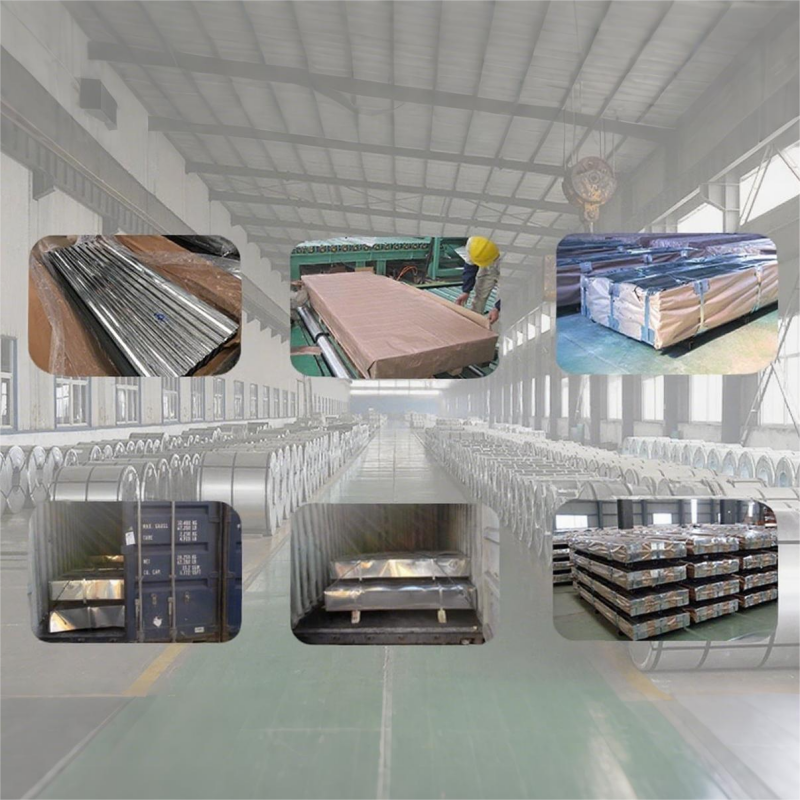

Production process

Uncoiling & Leveling

Unwind the pre-coated colored steel coil and level it to eliminate internal stress and ensure flatness.

Production Process

Corrugation Forming

Pass the coil through rollers to shape it into corrugated patterns, using controlled pressure to prevent coating damage.

Production Process

Cutting & Edge Trimming

Cut to specified lengths and smooth edges to remove burrs.

Production Process

Post-processing (Optional)

Additional steps like punching holes or applying protective films.

Production Process

Quality Inspection & Packaging

Check coating integrity, dimensions, and performance; package with protective materials for storage/shipment.

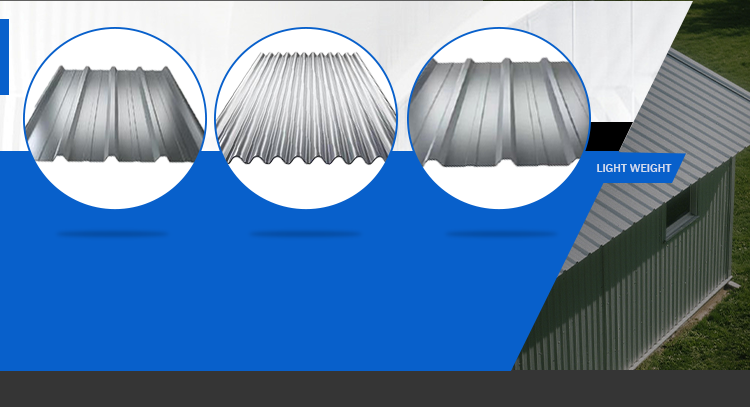

Production Application

Footwear abrasion solutions

Ndustrial buildings: Used in construction of factories such as machinery manufacturing, chemical industry, and electronics factories.

Agricultural facilities: Suitable for greenhouse sheds and livestock farms.

Commercial buildings: Used in warehouses, logistics centers, shopping malls, etc.

Temporary structures: Used for construction site sheds and mobile houses.

Packaging field: Packaging and transportation pallets for household appliances, glass products, ceramic products, etc.

Other fields: advertising promotion, vehicle interior, etc.