DX51D Galvanized steel Coils GI for Home Appliance

description1

Production description

Product name |

Galvanized steel coil |

Width |

100-1250mm, 1000mm, 1219mm, 1250mm, 1500mm or according to customer's requirement |

Thickness |

0.12-2.5mm, 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm or customer's requirement |

Coil weight |

3-10 tons or customer's requirement |

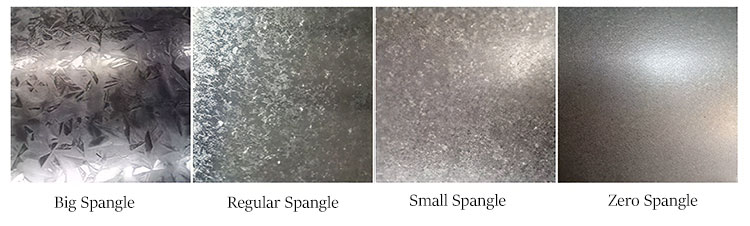

Surface Structure |

Slightly oiled,Galvanized |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Grade |

DC51D+Z,DC52D+Z,DC53D+Z, DX51D+Z, SGCC, SGCD, SGHC, SGH340, DX51D+AZ, DC51D+AZ, DX51D+ZAM, DC51D+ZAM, SECC, DX51D+ZF, DC51D+ZF, CSA, CSB, SS33, S350GD |

Coating Weight |

30-300g/m2 |

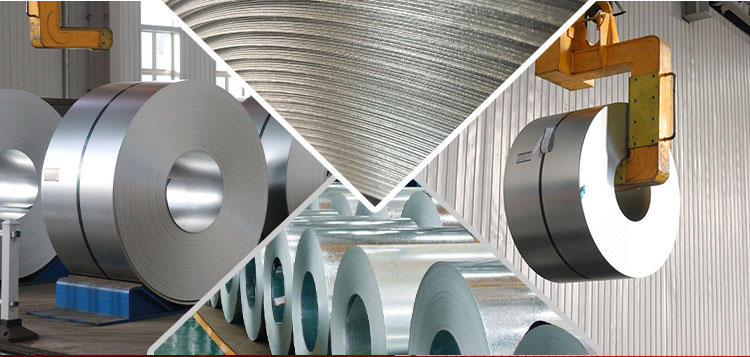

Hot dip galvanized steel coils are produced using hot-rolled or cold-rolled steel strips as substrates through a continuous hot-dip galvanizing process. The hot-dip galvanized sheet is supplied as a rectangular flat plate through cross cutting; Hot dip galvanized coils supplied in rolls. The process of immersing surface clean metal materials or parts in molten zinc solution and utilizing the physical and chemical reactions occurring at the interface to form a layer of metallic zinc on the surface, thereby achieving the purpose of corrosion prevention. Hot dip galvanized sheet coils can be divided into hot-rolled galvanized sheet coils and cold-rolled galvanized sheet coils, which are mainly used in fields such as construction, household appliances, automobiles, containers, transportation, and home industry. Galvanized coils have strong corrosion resistance, good surface quality, benefits from deep processing, and economic practicality.

Production Application

Footwear abrasion solutions

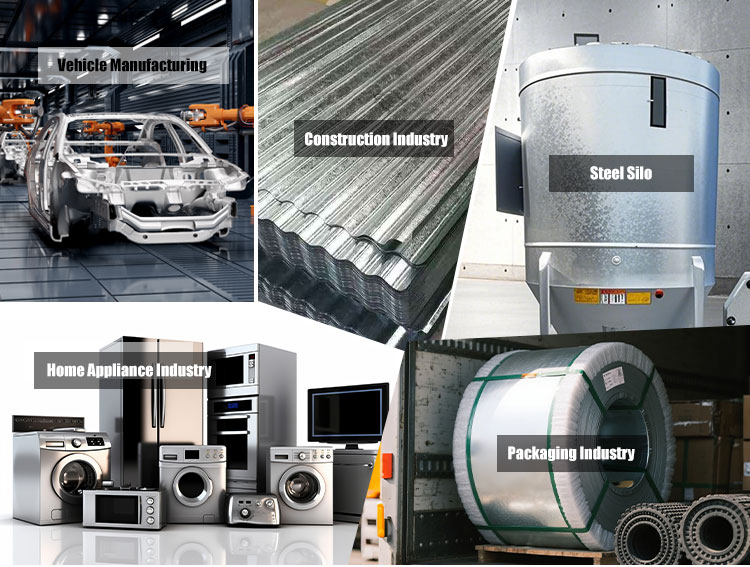

In the construction field: Used for building keels, steel structure frames, roof panels, wall panels, etc., ensuring structural stability and resisting wind and rain erosion.

In the home appliance industry: Used for manufacturing casings of home appliances such as refrigerators and air conditioners, as well as internal components like brackets, combining aesthetics and durability.

In the automotive manufacturing: Applied to vehicle body panels, chassis, and suspension system components, enhancing safety and durability.