Customized Services Mild Carbon Hot Rolled Steel Coils

description1

Production description

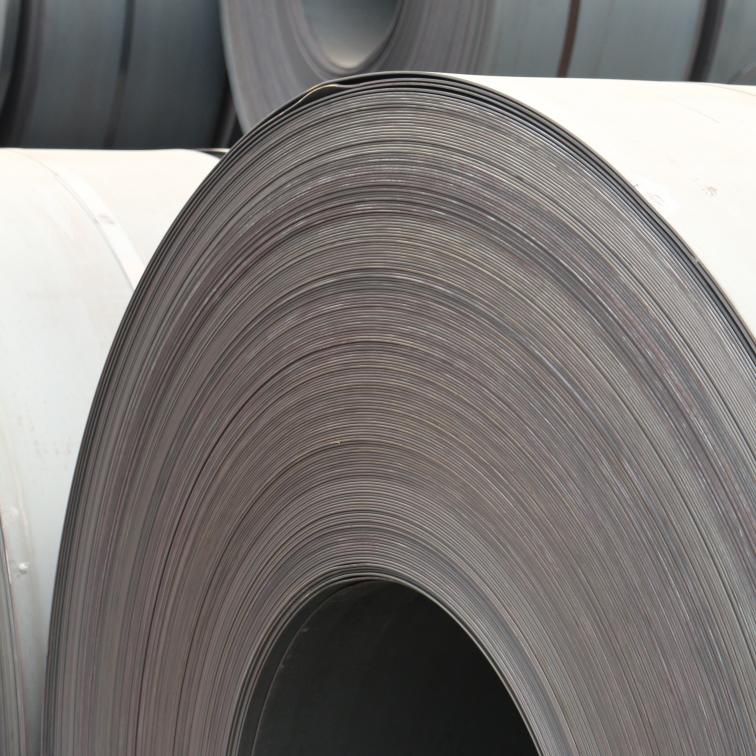

Product name |

Hot rolled steel coil |

Width |

600mm-2000mm or according to customer's requirement |

Thickness |

0.7~25.0mm or customer's requirement |

Roll weight |

1-30 tons |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN,ROCT |

Grade |

Q195L,Q235B,Q355B,SPHC |

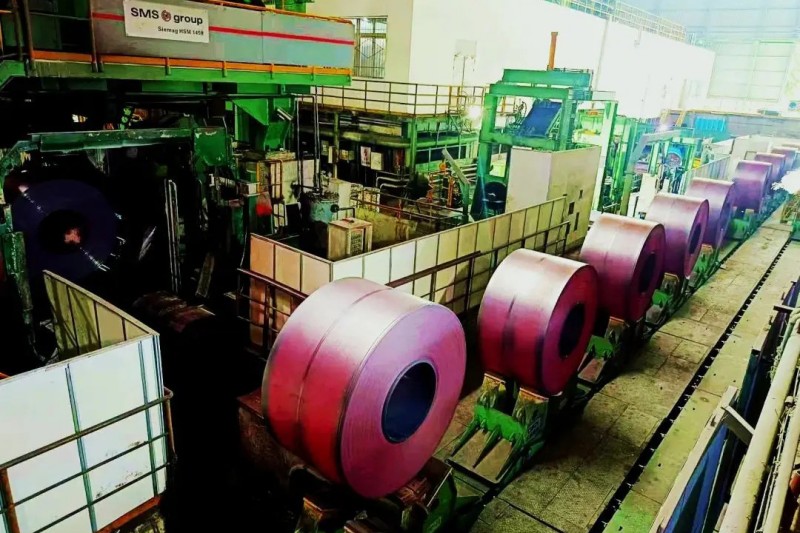

Production process

Raw Material Preparation

Select premium carbon steel billets and inspect for quality.

Production Process

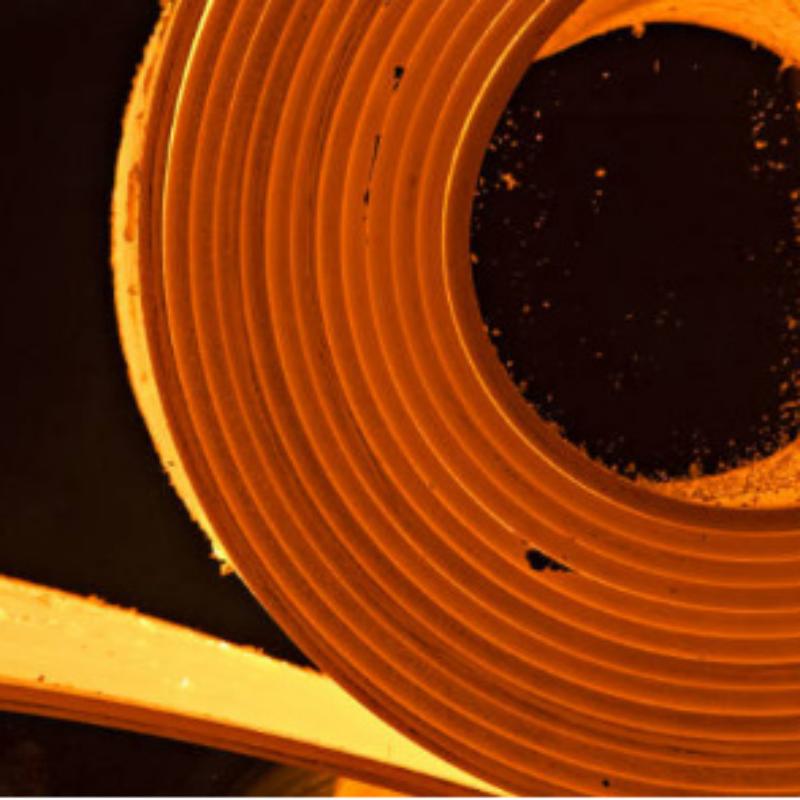

Heating

Heat billets in a furnace to a high temperature for easy deformation.

Production Process

Rough Rolling

Use rolling mills to reduce the thickness and shape the billets.

Production Process

Finish Rolling

Further refine dimensions and surface quality with precise control.

Production Process

Cooling

Rapidly cool the coils to fix the structure and properties.

Production Process

Coiling

Wind the cooled steel strips into coils.

Production Process

Inspection

Check dimensions, surface, and mechanical properties before delivery.

Production Application

Footwear abrasion solutions

1. Construction: Used for beams, columns, and steel frames, ensuring structural stability.

2. Automotive: Applied to vehicle chassis parts, providing strength and durability.

3. Machinery: Shaped into machine tool bodies and gears, meeting mechanical requirements.

4. Pipeline: Processed into pipes for oil, gas transport, able to withstand high pressure.

5. Shipbuilding: Constructs ship hulls, enduring marine conditions.

6. Agriculture: Manufactures farm machinery, handling heavy - duty work.