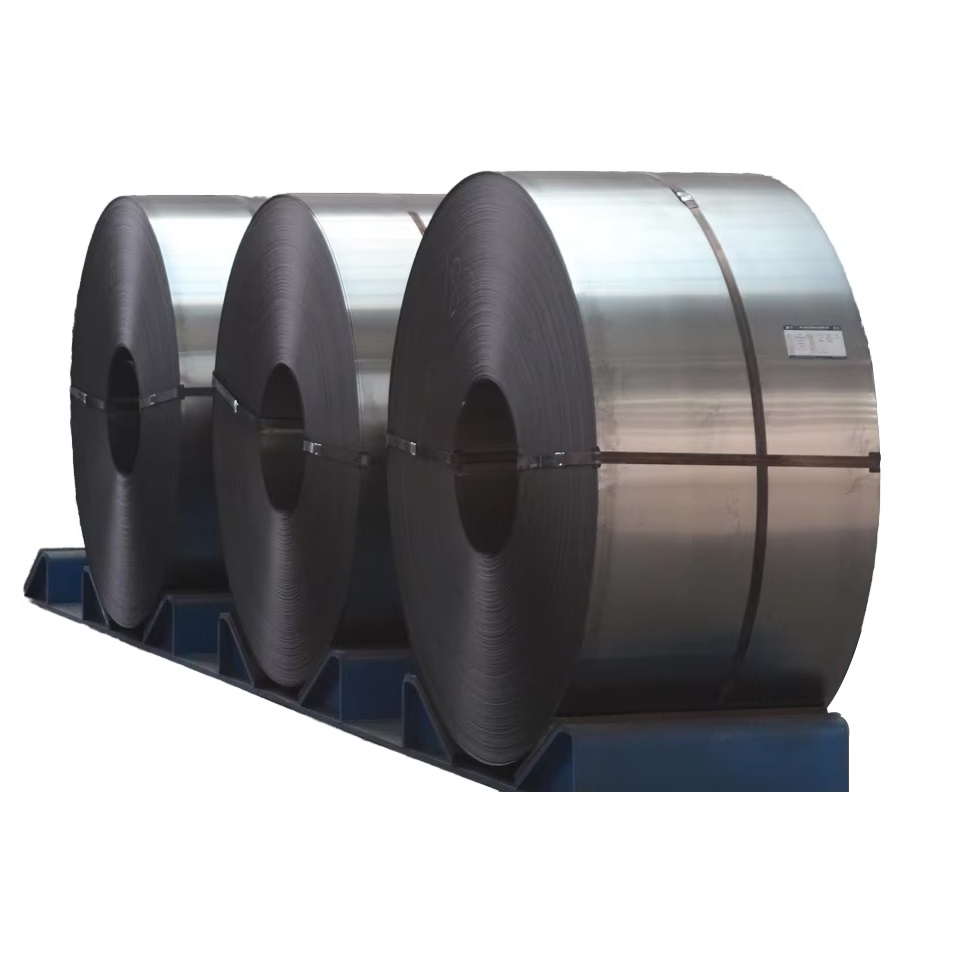

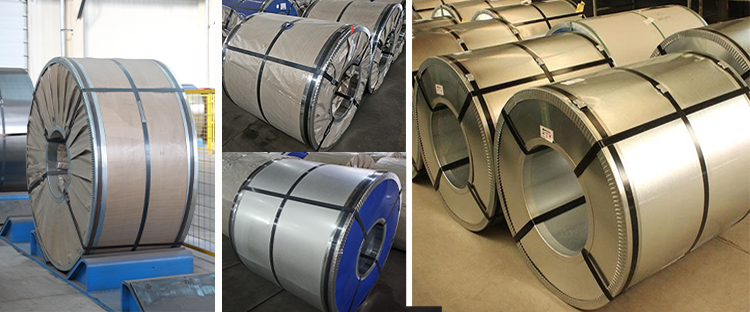

Chinese Wholesale Cold Rolled Coil Steel Strip 1219mm 1.0mm

description1

Production description

Product name |

Cold rolled steel coil |

Width |

32mm-1500mm, 1000mm, 1200mm, 1250mm or according to customer's requirement |

Thickness |

0.12mm-2.2mm, 0.5mm, 1.0mm, 1.2mm, 1.9mm, 2.5mm or customer's requirement |

Roll weight |

5-28 tons |

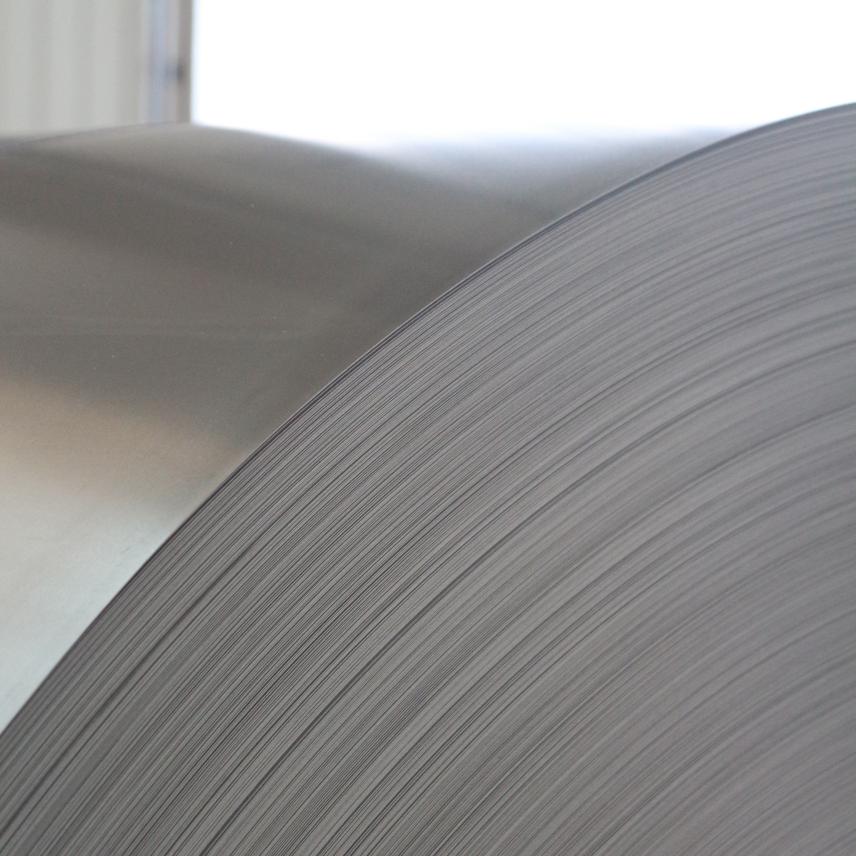

Surface Structure |

Oily to apply |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Grade |

DC01, DC03, SPCC, SPCD,ST12,ST13 |

Cold rolled steel coil, a versatile industrial basic material blending practicality and flexibility, boasts extensive application scenarios. In architecture, it serves directly as core raw material for steel structural components, wall panels and more. The electrical manufacturing industry also relies on it to produce shells, internal frames and other parts for home appliances like refrigerators and air conditioners, with its excellent performance meeting strict product material requirements. Additionally, it has strong processing potential — capable of undergoing coating, cutting, stamping, welding and other treatments as needed. This enables it to adapt to production demands in more segmented fields such as automobile manufacturing, mechanical equipment production and precision instrument assembly, truly achieving flexible transformation from basic raw material to diversified finished components.

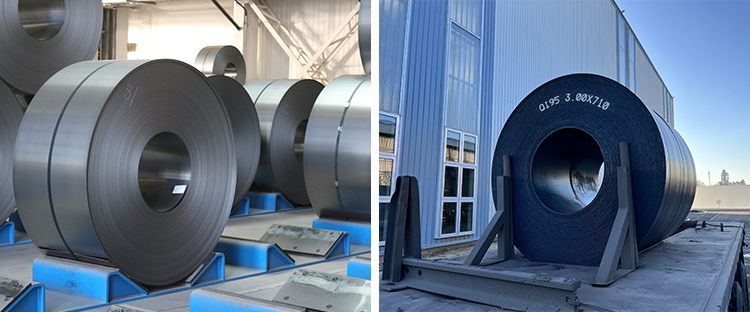

Various types of packaging methods are available for selection.

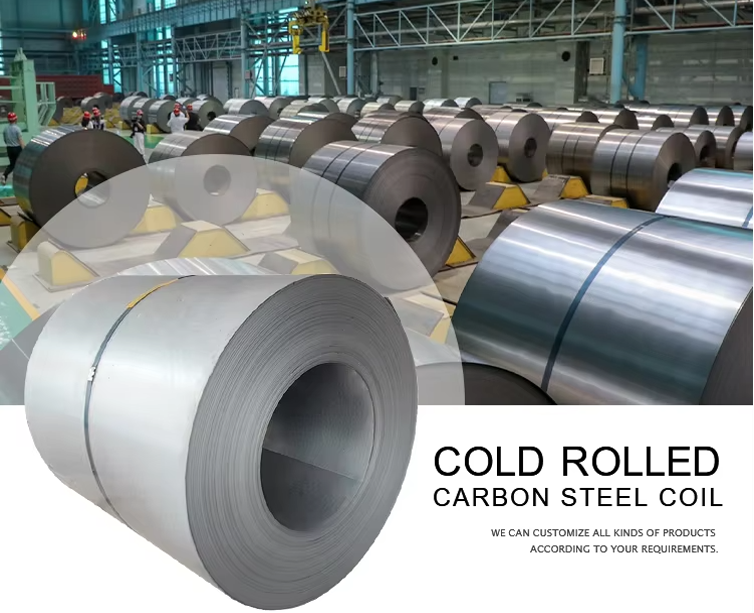

Production process

Raw Material Selection

Premium hot-rolled coils meeting strict quality standards are carefully chosen.

Production Process

Pickling

Immersed in acid, hot-rolled coils remove oxide scale for a clean surface.

Production Process

Rolling

Multiple - roll stands reduce thickness precisely, with computer - controlled optimization.

Production Process

Annealing and Cold Rolling

Annealing is divided into continuous annealing and overlay annealing, and its principle is to eliminate stress, improve mechanical properties, and refine grains through heat treatment.

Production Process

Skin Pass Rolling

Light rolling enhances surface quality and flatness.

Production Process

Finishing

6.Processes like coating, slitting, and winding shape the final product.

Production Process

Quality Control

Rigorous inspections cover dimensions, surface, mechanics, and chemistry. Only qualified coils are delivered.

Jinxuan Steel's advanced equipment, strict control, and expert team ensure top - quality cold - rolled coils for diverse needs.

Production Application

Footwear abrasion solutions

1. Automotive Sector: Manufactures vehicle body panels (doors, hoods, etc.) and structural parts, ensuring safety, stability, and good appearance.

2. Home Appliance Field: Forms the shells of refrigerators, washing machines, etc., enhancing durability and aesthetic appeal.

3. Electrical Industry: Used for electrical equipment enclosures like distribution boxes and transformer shells, guaranteeing operational safety.

4. Construction Area: Applied in roofing, walling, and flooring, such as color - coated panels for roofs and light - steel keels for buildings.

5. Metal Products: Serves as a raw material for furniture, office gear, and metal containers, enabling diverse product shapes.

6. Machinery Manufacturing: Fabricates machine tool beds, frames, and parts, ensuring equipment precision and long - term use.

7.As raw materials: used for manufacturing cold-rolled steel strips, cold-rolled sheets, galvanized coils, color coated coils, corrugated sheets, etc

keywords:Cold rolled steel coils,Cold-Rolled Steel Coils,Cold Rolled Mild Steel Coils,Cold Rolled Coils (Steel),Cold Reduced Steel Coils,Cold-Rolled Coiled Steel,Cold-Rolled Carbon Steel Coils,CR Steel Coils,Cold-Rolled High-Strength Steel Coils,Cold Rolled Steel Strip Coils,CRC STEEL