In the realm of construction, safety and strength are paramount. "Steel Rebars are the backbone of any concrete structure," emphasizes Dr. Lisa Chan, a leading expert in structural engineering. Without these essential components, buildings may lack the integrity required to withstand external forces.

Steel Rebars provide crucial tensile strength. They enhance the stability of structures by preventing cracks. Their durability plays a vital role in a building's lifespan. The cost-effectiveness of Steel Rebars makes them appealing. However, improper installation can lead to severe consequences. Even a small oversight may compromise safety.

Project managers must prioritize quality when sourcing Steel Rebars. Conducting regular inspections during construction is necessary. A robust structure is built on strong foundations, and these rebars are fundamental in achieving that goal. When considering construction safety, the importance of Steel Rebars cannot be overstated.

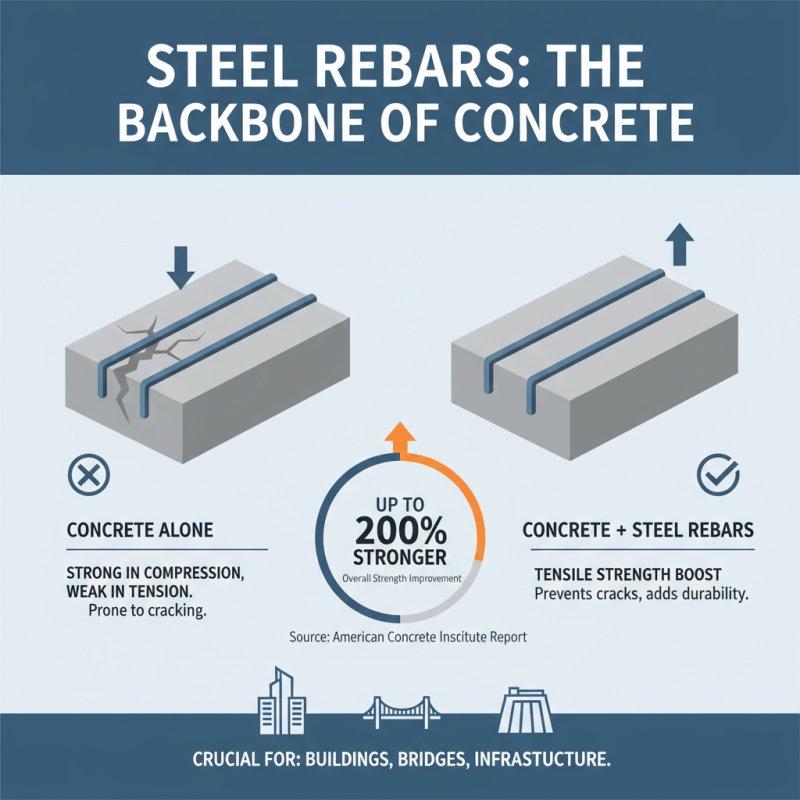

Steel rebars play a crucial role in reinforcing concrete structures. They provide tensile strength, which concrete lacks. Concrete is strong in compression but weak in tension. According to a report by the American Concrete Institute, adding steel rebars improves the overall strength of concrete by up to 200%. This enhancement is vital for ensuring durability in buildings, bridges, and other structures.

When rebars are embedded in concrete, they create a composite material that can withstand various forces. In earthquake-prone areas, well-reinforced concrete can absorb shock and prevent catastrophic failures. Experts suggest that structures with adequate rebar reinforcement have a 50% lower chance of structural failure during significant seismic events. However, achieving this ideal reinforcement requires precise calculations and placement, which not all contractors get right.

Improper installation can lead to serious issues. Insufficient coverage of rebars or incorrect spacing may compromise the integrity of the structure. A study by the National Institute of Standards and Technology noted that about 30% of reinforced concrete failures result from inadequate rebar practices. Therefore, continuous training and adherence to building codes are critical in the construction industry.

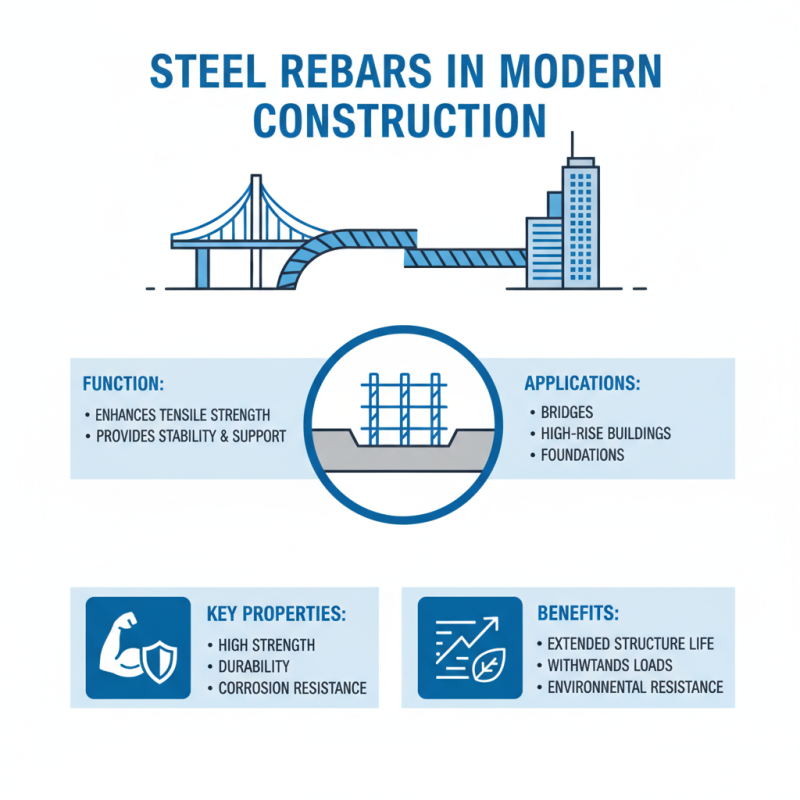

Steel rebars are critical components of modern construction. They enhance the tensile strength of concrete, providing stability and support. This combination is vital for structures like bridges and buildings. The properties of steel rebars include high strength and durability. They can withstand various environmental conditions and loads. Corrosion resistance is also an important feature. This extends the life of the structures they reinforce.

There are different types of steel rebars. Common types include deformed and smooth rebars. Deformed rebars have ridges that improve bonding with concrete. Smooth rebars are easier to handle and cut, but they offer less grip. The choice of rebar type can impact a project’s outcome. It’s important to understand their properties to ensure safety.

In construction, sometimes the focus on rebar quality is lacking. Not all steel is created equal. Inferior materials can affect structural integrity. Regular inspections are necessary. Awareness of manufacturing standards is crucial. Understanding these factors can prevent potential failures. Each project should prioritize safe practices and quality materials for better results.

Steel rebars play a crucial role in construction by enhancing structural integrity. They are embedded in concrete to provide tensile strength. Without rebars, concrete alone would not withstand forces well. Concrete is strong in compression, but weak in tension. This is where rebars come in, compensating for that weakness.

When designing structures, the load-bearing capacity must be considered. Rebars help distribute the weight evenly. They also improve the ductility of concrete. This means structures can absorb energy during events like earthquakes. However, improper placement of rebars can lead to issues. If they are too close to the surface, they may rust. Corrosion weakens the structure over time.

The installation process is critical. Each layer of rebar must be correctly positioned. Misalignment can lead to structural failure. Builders need to ensure that proper spacing and overlap are maintained. These factors can be easily overlooked in the rush to finish a project. It’s essential to reflect on these details to ensure safety and durability.

Steel rebars play a vital role in construction safety. Their presence enhances the tensile strength of concrete structures. Concrete is excellent in compression, but it fails in tension. By embedding steel rebars, we create a composite material that harnesses the strengths of both. According to a report by the World Steel Association, structures with quality steel reinforcement show a 30% increase in load-bearing capacity.

Using substandard rebars poses severe safety risks. Inadequate reinforcement can lead to catastrophic failures. Recent studies indicate that nearly 27% of building collapses are linked to poor-quality materials. Proper testing and certification of steel rebars are essential. Engineers must ensure compliance with established standards. A focus on using reliable sources of steel will mitigate risks significantly.

In addition, maintaining quality during installation is crucial. Poor practices can lead to misalignment and inadequate bonding. These issues weaken the overall structure. A National Institute of Standards report highlights that nearly 40% of rebar installations do not meet structural specifications. This statistic underscores the need for vigilance and training. Implementing best practices will significantly enhance safety and longevity in construction projects.

| Dimension | Specification | Safety Implications | Strength Characteristics |

|---|---|---|---|

| Diameter | 10 mm - 40 mm | Higher load capacity reduces risk of structural failure | Enhanced tensile strength |

| Grade | Grade 60, Grade 75 | Quality grades enhance safety margin | Increased yield strength |

| Yield Strength | 60,000 psi - 75,000 psi | Prevents bending or deformation under stress | Maximizes structural durability |

| Corrosion Resistance | Coated or uncoated | Reduces risk of rust-related deterioration | Maintains structural integrity over time |

| Thermal Expansion | Low thermal expansion coefficient | Minimizes cracking under temperature changes | Ensures stability in varying climates |

In construction, rebar is vital. However, many face challenges during its implementation. For instance, miscalculations in spacing can weaken structures. That's a critical issue. Proper placement is essential for strength. Yet, many workers overlook it. Regular training is needed to ensure everyone understands best practices.

Corrosion is another common challenge. Steel bars can rust over time if not treated properly. In humid environments, this issue becomes worse. Projects must include protective coatings. Choosing the right type of rebar material can also help. Some options work better in specific conditions.

Additionally, labor shortages can impact the quality of rebar installation. New workers may not have the required skills. Therefore, mentorship programs become crucial. Veterans in the field can share valuable knowledge. Encouraging a culture of safety and expertise is fundamental for project success. Investing in training pays off in the long run.