Selecting the right Tube Steel for your project is crucial. The tube steel market has been growing steadily. Reports indicate the global market size reached $50 billion in 2022. This shows a strong demand across various industries.

When choosing Tube Steel, consider factors like strength, weight, and corrosion resistance. It is important to match these properties to your project's specific needs. A mismatch can lead to costly failures or delays. According to industry data, over 30% of construction projects face setbacks due to improper material selection.

Additionally, understanding the different grades and sizes of tube steel is vital. Various applications require distinct specifications, making this choice complex. Many professionals emphasize the importance of research and consultation. Yet, even experienced engineers sometimes overlook critical details. This ongoing challenge highlights the complexity of material selection.

When selecting tube steel for your project, consider the different types available. Tube steel typically comes in two main shapes: round and rectangular. Each type has its own unique properties.

Round tubes often provide strength in multiple directions. This makes them ideal for structures requiring uniform load distribution. On the other hand, rectangular tubes have a larger surface area, which can be great for welding.

The material quality also plays a crucial role. Standard steel, for example, is common for general-purpose applications. Stainless steel, however, is preferable for projects exposed to moisture. It offers greater resistance to corrosion. Galvanized steel is another option. It is coated to increase durability in harsh environments. Choosing the right type can be challenging, especially when you consider factors like weight and tensile strength.

Consider the dimensions needed for your project. A large diameter might seem appropriate, but it can add weight. Conversely, a small diameter could compromise strength. It’s essential to strike a balance. Sometimes, an initial choice may not work as expected. Being open to adjustments can lead to better outcomes.

Selecting the right tube steel for your project is critical. Several key factors can influence your decision-making process. One primary consideration is the intended application. Different projects require different mechanical properties. According to industry reports, structural applications often demand higher strength steel, while lighter applications can use lower grades.

Another essential factor is the size and shape of the tube. Common shapes include round, square, and rectangular. Each shape provides different strength and stiffness properties. For instance, round tubes often handle torsional stress better than square tubes. Size affects weight considerations too, which can impact transportation and installation expenses.

**Tip:** Always consult with structural engineers. They can provide insights specific to your project requirements. Choosing a tube steel that feels right in theory might not work well in practical applications.

Another important aspect is the environmental factors. Exposure to moisture or chemicals can affect the longevity of tube steel. Use galvanized or painted options if the environment is corrosive. Industry data shows that this can increase lifespan by over 50%.

**Tip:** Consider your project's lifecycle. Sometimes cheaper materials end up costing more in maintenance. Calculate long-term costs, not just initial prices, before making a decision.

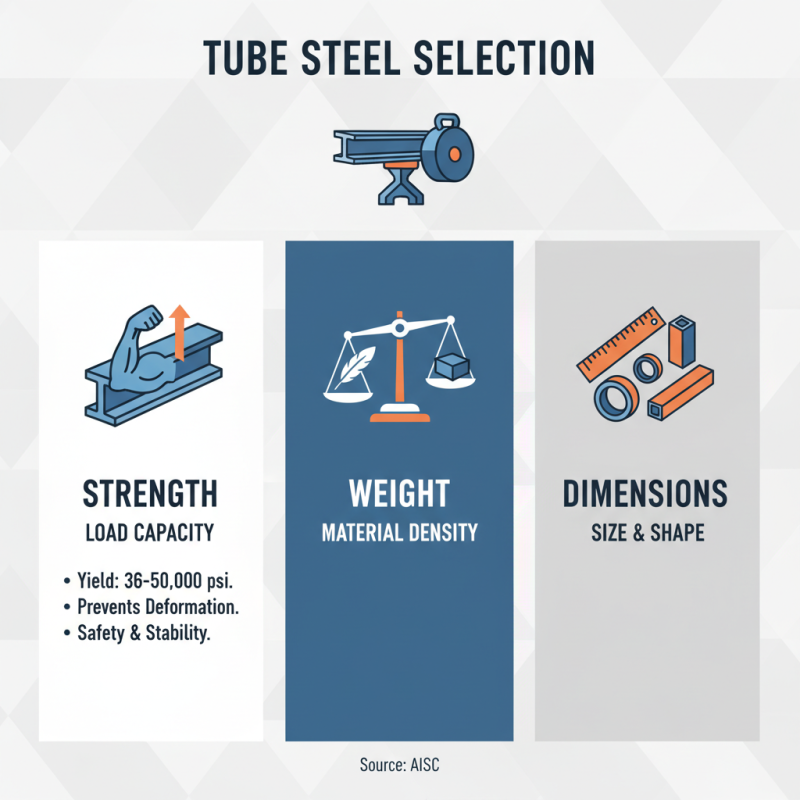

Selecting the right tube steel for your project involves critical evaluation of specifications like strength, weight, and dimensions. Strength defines how much load the steel can bear without deforming. According to the American Institute of Steel Construction, typical yield strength for structural steel can range from 36,000 to 50,000 psi. Understanding these figures is essential for ensuring safety and stability in your structure.

Weight is another factor. Different wall thicknesses and material compositions impact the overall weight of tube steel. A lighter tube allows for easier handling and transportation. However, a heavier option might provide added strength. A recent industry report suggests that every extra pound of steel can affect the overall design layout and carrying costs.

Dimensions also play a pivotal role. Common tube steel sizes range from 1 inch to 12 inches in diameter. Selecting the wrong dimensions can lead to structural inefficiencies or even failures. While it may seem easier to choose a commonly available size, reflection on specific project needs is crucial. Avoiding a one-size-fits-all approach can prevent costly mistakes down the line. Always consider your unique project requirements to select the most appropriate tube steel.

When choosing tube steel, weighing cost against quality is crucial. Many projects hinge on using the right materials. Tube steel often comes in various grades and finishes. A 2021 report by the Steel Structure Association highlights that using higher-grade steel can enhance a project's longevity by up to 30%. However, this comes at a price. An excess of $50 per ton for premium quality may seem steep at first.

Cost-cutting can lead to issues. In recent years, reports indicated that projects using lower-grade tube steel suffered increased maintenance costs. On average, these projects faced repair bills up to 15% higher than those that invested in quality materials. The temptation to save can have long-term repercussions. Quality ensures safety and structural integrity. Cheaper options may initially fit budgets, but the risks can outweigh short-term savings.

When selecting tube steel, it’s vital to consider both immediate costs and future expenses. Balancing these elements is often not straightforward. Take time to assess supplier credibility and possible lifetime costs. Sometimes, the best decision might not be the most obvious one, and finding that balance requires careful thought.

Selecting the right tube steel for your project requires careful consideration of specific applications. Tube steel comes in various grades, sizes, and shapes. Each grade has unique properties that suit different uses. For instance, mild steel tubes are often preferred in structural applications due to their strength and flexibility. According to industry reports, structural steel accounts for over 50% of total steel usage in construction.

When choosing tube steel, consider the load requirements of your project. Will it bear heavy weights? Is it for a lightweight structure? This assessment is crucial. Many projects fail to account for potential overloads. A structural analysis can prevent future issues. The thickness of the tube also matters. Thicker tubes offer more support but add weight. Balance is key here.

Corrosion resistance should not be overlooked. In humid or harsh environments, choosing galvanized or stainless steel can extend the material's lifespan. A report from the American Institute of Steel Construction highlights that corrosion can reduce the life of structures by up to 50%. Familiarize yourself with the environment where the tube will be used. Reflecting on these details may save time and costs later. It's easy to get it wrong if you rush the selection process. Dialogue with professionals can provide insights that enhance your choices.

This chart displays the tensile strength and weight of various types of tube steel commonly used in projects. Selecting the appropriate type is crucial for balancing structural integrity and weight considerations.