When embarking on a project that requires structural support, choosing the right Angle Bar is crucial. Expert engineer Mark Johnson emphasizes, "Selecting the best angle bar can make or break your project's success." This advice resonates deeply in the construction and manufacturing industries.

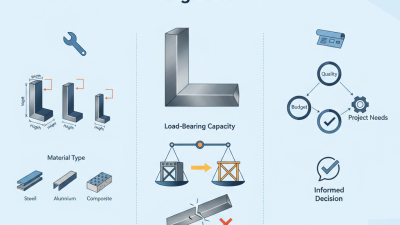

Angle Bars are versatile materials used in various applications, from building frameworks to fabricating machinery. When making your selection, consider factors such as the material type, width, and thickness. Each project may demand different specifications. A miscalculation here can lead to unexpected setbacks or even project failure.

Understanding your project's unique requirements is key. You might think steel is universally ideal, but sometimes lighter materials can offer better performance. Also, be aware of the quality standards that different suppliers maintain. At times, it’s tempting to cut costs, but a poor-quality angle bar can jeopardize safety and stability. Reflect on these elements as you navigate your decision-making process.

When it comes to angle bars, understanding the types available is crucial. There are mainly two types: equal leg and unequal leg angle bars. Equal leg bars have legs of the same length, making them universally versatile. These are ideal for structural supports in various applications. On the other hand, unequal leg bars provide more flexibility in design. Their differing leg lengths cater to specialized needs, such as trusses or frames.

Material choice also plays a significant role. Steel angle bars are common due to their strength and durability. Aluminum angle bars are lighter, making them suitable for projects requiring less weight. Stainless steel options offer corrosion resistance, ideal for outdoor settings. It's essential to consider the environment where the angle bar will be used.

Moreover, the thickness of the angle bar affects its load-bearing capacity. A thicker bar can handle more weight but may be overkill for lighter projects. Sometimes, the choice may be limited by availability, which adds complexity. Reflect on your specific needs before making a decision. Choosing the right angle bar requires a balance of factors to ensure optimal performance for your project.

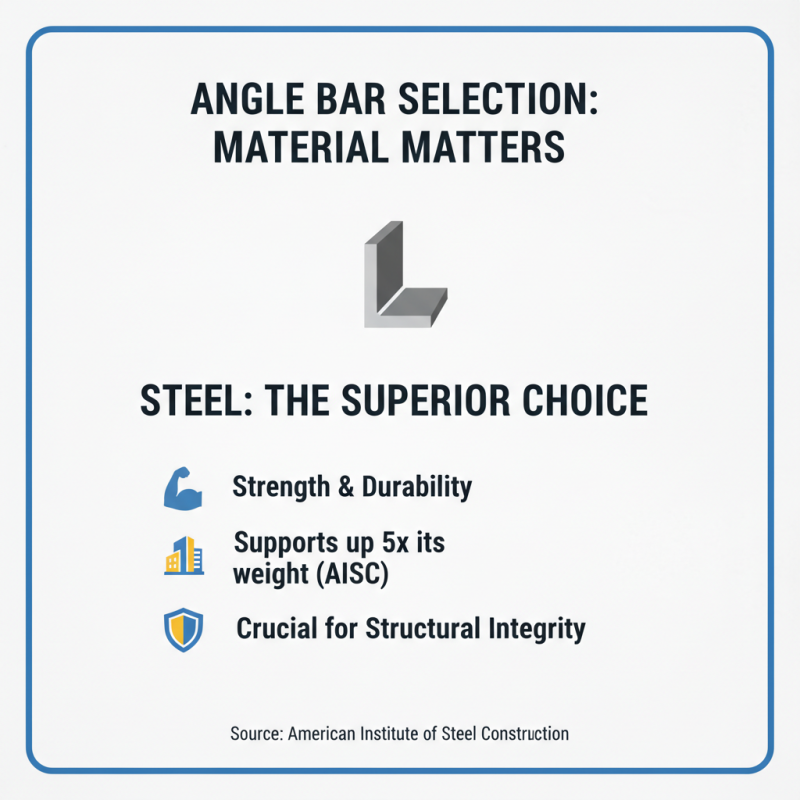

When selecting an angle bar for your project, material choice is crucial. Steel is the most popular option due to its strength and durability. According to a report by the American Institute of Steel Construction, steel angle bars can typically support loads up to five times their weight. This is particularly important in construction applications where structural integrity is paramount.

Aluminum offers a lighter alternative. It's resistant to corrosion, making it suitable for outdoor projects. However, aluminum’s strength-to-weight ratio is not as favorable as steel. A survey by the Aluminum Association indicates that while aluminum angle bars are easier to work with, they may not always meet heavy load requirements, which could lead to project complications.

Other materials, such as stainless steel and composites, present unique benefits and drawbacks. Stainless steel provides excellent resistance to rust while maintaining good tensile strength. But the cost can be significantly higher than other options. Composites might offer innovative uses, but they often require specialized knowledge for optimal installation. Consider these factors carefully; a bad choice can compromise the entire project.

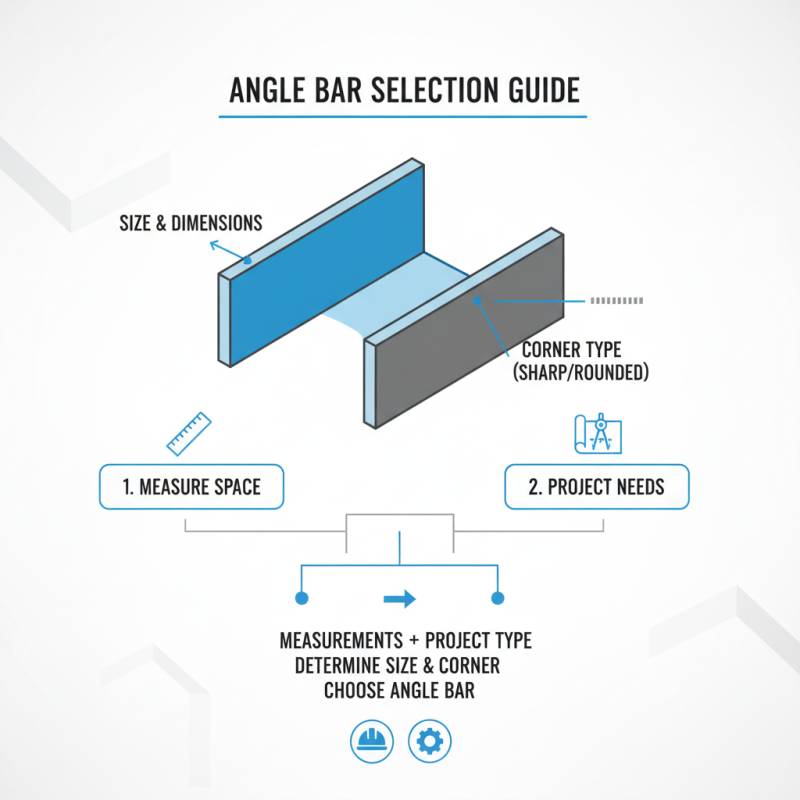

Choosing the right angle bar starts with understanding your project’s needs. The size and dimensions are crucial. Measure the space where the angle bar will fit. Are the corners sharp or rounded? These factors will dictate the size you need.

Consider the thickness of the angle bar too. A thicker bar can offer better strength, but it might be heavier and harder to work with. This could slow down your project. On the other hand, lighter bars may bend under stress. Balance is key.

Sometimes, the selection might not feel obvious. You may think you’ve made the perfect choice, but the project may reveal flaws later. It's vital to reflect on your initial decisions. Each project is unique and requires thoughtful evaluation of fit and function.

When selecting an angle bar, understanding load capacity and strength is crucial.

Angle bars, commonly made from steel, are used in various structural applications.

The load capacity often depends on factors like length, thickness, and material grade. According to the American Institute of Steel Construction, a standard angle bar can support a load ranging from 15,000 to over 30,000 pounds, depending on its size and material specifications.

Evaluating strength requirements involves understanding the project’s demands. For instance, a construction project needing high durability may require a grade of steel like A992, which has a minimum yield strength of 50 ksi. On the other hand, a less critical application might suffice with a lower grade.

Misjudging these specifications can lead to inadequate support, which could compromise the overall integrity of the structure.

It’s worth noting that not all projects are straightforward. Factors such as environmental conditions and potential wear over time can impact performance. A study by the Steel Construction Institute indicates that angle bars subjected to extreme weather can experience reduced load-bearing capabilities.

Therefore, reflective consideration of both immediate and long-term needs is essential for selecting the correct angle bar.

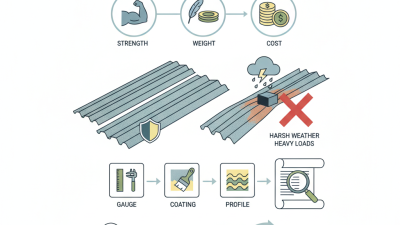

When selecting an angle bar for your project, it’s crucial to consider environmental factors. Corrosion resistance is one of the biggest concerns. Without proper resistance, angle bars can deteriorate quickly. This affects your project’s integrity.

Different coating options are available. Powder coating is popular due to its durability. However, it can wear off in harsh conditions. Hot-dip galvanization offers excellent protection but can be more costly. Think about the long-term implications of your choice.

Some projects may not be exposed to extreme elements. Yet, even mild conditions can lead to unexpected issues. Assessing the environment carefully is key. It’s sometimes tempting to rush this decision but taking the time can yield better results. Reflect on these factors before making your choice.

| Material | Corrosion Resistance | Coating Options | Applications |

|---|---|---|---|

| Mild Steel | Low | Galvanized, Painted | General Construction, Structural |

| Stainless Steel | High | Polished, Brushed | Food Industry, Marine |

| Aluminum | Moderate | Anodized, Powder Coated | Aerospace, Automotive |

| Carbon Steel | Moderate | Painted, Hot Dip Galvanized | Construction, Machinery |

| Copper-Nickel Alloy | Very High | Not Applicable | Marine, Chemical Processing |