In the evolving landscape of construction and manufacturing, the role of Angle Bars has become increasingly significant. As noted by industry expert John Smith, "Angle Bars are the backbone of structural integrity." This statement reflects the growing reliance on these versatile components in various applications.

Looking ahead to 2026, several trends are shaping the Angle Bar industry. Sustainability is one critical aspect. Many companies are exploring eco-friendly materials and manufacturing practices. Additionally, advancements in technology are streamlining production processes, but some struggle to keep up with these innovations. The competition is fierce, and those who fail to adapt may fall behind.

Furthermore, the demand for custom Angle Bars is rising. Tailored solutions are becoming essential for unique project requirements. However, the challenge lies in maintaining quality while meeting these specialized requests. As the industry continues to evolve, it’s clear that Angle Bars will remain pivotal in construction and manufacturing, but the journey ahead is not without its obstacles.

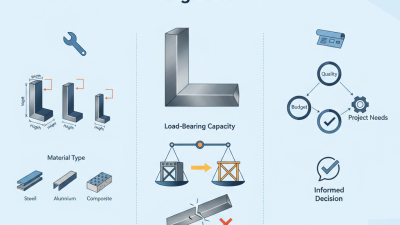

As we look forward to 2026, the angle bar's role in construction and manufacturing is evolving. These structural elements are getting more attention due to their adaptability. In modern architecture, angle bars offer both strength and design flexibility. They can be found in various applications, from framing to support systems.

Sustainable materials are gaining traction. Many manufacturers are exploring eco-friendly options for angle bars. This trend reflects a broader commitment to reducing environmental impact. Yet, the challenge lies in sourcing and producing these materials efficiently. Innovations are emerging, but not all are viable for mass production. Moreover, there is a growing emphasis on shorter lead times, prompting manufacturers to rethink their supply chains.

The impact of smart technology cannot be ignored. Integrating sensors into angle bars can enhance performance monitoring. However, this raises questions about cost and complexity. Not every project may justify these advancements. Balancing innovation with practical application remains a critical conversation. The landscape of angle bars is shifting, but not without debate and consideration of existing practices.

The year 2026 is set to witness significant changes in the production of angle bars. Materials play a pivotal role in shaping these trends. According to industry forecasts, steel remains the dominant material due to its strength and versatility. However, alternative materials are gaining attention. Aluminum, with its lightweight properties, is increasingly being utilized for specific applications. Recent studies suggest that the global angle bar market will grow by nearly 4% annually, driven by infrastructure development.

Recycling is another key focus. The demand for sustainable practices pushes manufacturers to explore recycled steel. This choice not only lowers costs but also contributes to environmental preservation. Reports indicate that recycled steel can reduce carbon emissions by up to 30%. However, challenges exist. The quality of recycled materials often varies.

Tips: Always consider material certifications when sourcing. Verify the consistency of recycled steel. It's essential for safety. Keep an eye on emerging materials, too. Innovation can lead to better efficiency in production processes. As trends evolve, adapting to new materials may provide a competitive edge.

| Material Type | Market Demand (%) | Production Cost ($/ton) | Key Applications | Sustainability Rating |

|---|---|---|---|---|

| Steel | 45 | 800 | Construction, Manufacturing | C |

| Aluminum | 30 | 1800 | Aerospace, Transportation | B+ |

| Copper | 15 | 6000 | Electrical, Plumbing | A |

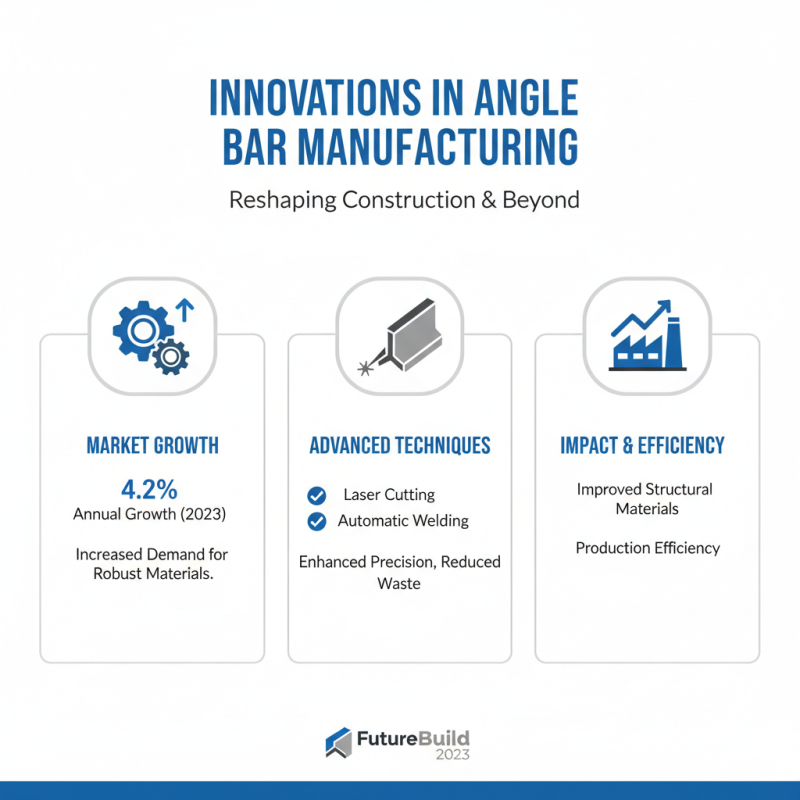

Innovations in manufacturing techniques for angle bars are reshaping the construction and manufacturing sectors. As of 2023, the global angle bar market is projected to grow at a rate of 4.2% annually. This growth reflects increased demand for robust structural materials. Advanced methods such as laser cutting and automatic welding are becoming more prevalent. These techniques enhance precision and reduce waste, driving efficiency in production.

Recent studies highlight that using automated systems can reduce manufacturing time by up to 30%. This is a significant gain, particularly in large projects. However, implementing these technologies presents challenges. Not all manufacturers are equipped to adapt swiftly. Training workers on new systems remains a critical concern. The industry must also balance innovation with cost management.

Sustainability is an emerging focal point. Reports indicate that 45% of manufacturers are looking to incorporate recycled materials in their angle bar production. This shift shows promise, but comes with hurdles. Quality control can vary when using recycled sources. The need for rigorous testing is essential to maintain structural integrity. The path ahead is filled with opportunities and challenges that will shape the future of angle bar manufacturing.

Sustainability is reshaping the angle bar industry. Reports indicate that over 50% of construction firms now emphasize green practices. This shift impacts the types of raw materials used. Recycled steel is becoming a priority. It reduces waste and energy consumption. However, sourcing recycled materials can be inconsistent. This inconsistency often leads to quality concerns.

Moreover, companies face challenges in adapting their manufacturing processes. The incorporation of eco-friendly methods can be costly. A study from the Construction Industry Research and Information Association suggests that sustainable technologies increase production costs by up to 15%. This creates a significant barrier for smaller manufacturers. Some struggle to justify the expense.

Still, the future is bright for sustainable angle bars. Demand for energy-efficient buildings is soaring. A report notes that the market for sustainably sourced materials is projected to grow by 20% annually. It's a trend that construction and manufacturing sectors cannot ignore. Balancing sustainability with cost-effectiveness remains a challenge. The need for innovation is critical, but it requires time and investment.

The future applications of angle bars in emerging construction projects show promising trends in design and engineering. According to the latest industry report from Grand View Research, the global construction sector is anticipated to reach $10 trillion by 2026. Angle bars, as versatile structural components, are being utilized to enhance the strength and stability of modern buildings. These materials are lightweight and easy to install, making them ideal for rapid construction techniques.

In regions that focus on sustainable practices, angle bars are becoming increasingly popular. Their recyclability and durability align with eco-friendly building initiatives. Projects in urban areas often use angle bars to support green roofs and facades. A study by Mordor Intelligence notes that the demand for these materials is expected to grow at a CAGR of 4.2% over the next five years. This reflects a shift towards innovative construction solutions, yet challenges remain in ensuring quality and compliance with rising safety standards.

Despite their advantages, there are concerns regarding the sourcing of raw materials for angle bars. The reliance on steel production often leads to high energy consumption. The industry must address these environmental impacts while keeping up with demand. As technologies advance, manufacturers need to explore alternative materials or production techniques to reduce carbon footprints. Balancing growth and sustainability will determine the future success of angle bars in construction projects.