All Kinds of High Quality Nuts customized

description1

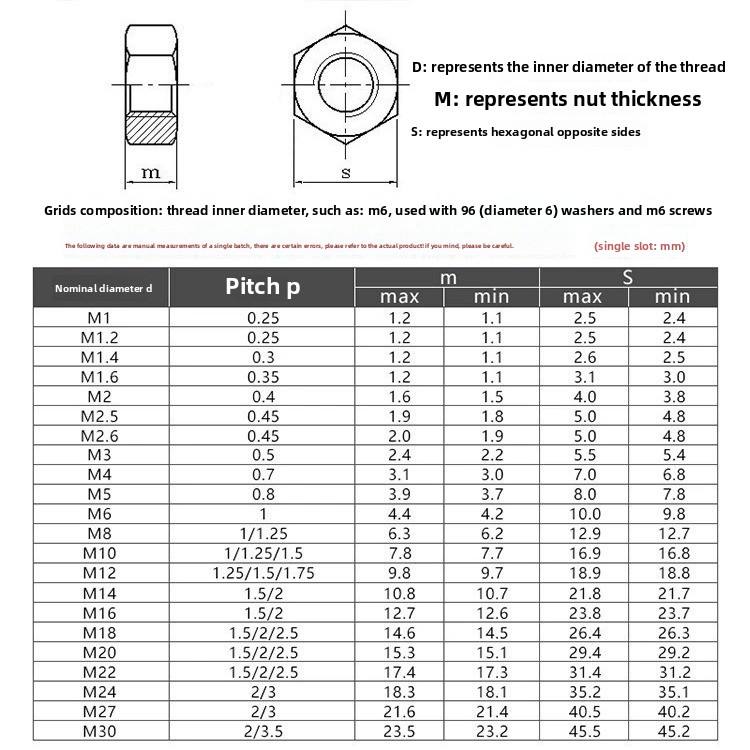

Production description

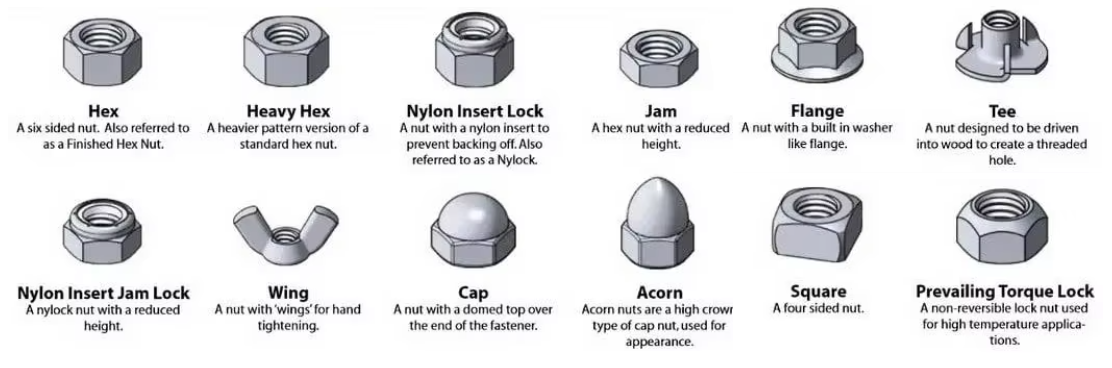

Main Shapes

Main Surface Treatments

Main Grades/Materials

is a paragraph

Thread types range from coarse (for quick insertion in wood) to fine (for precise, high-torque applications in metal).

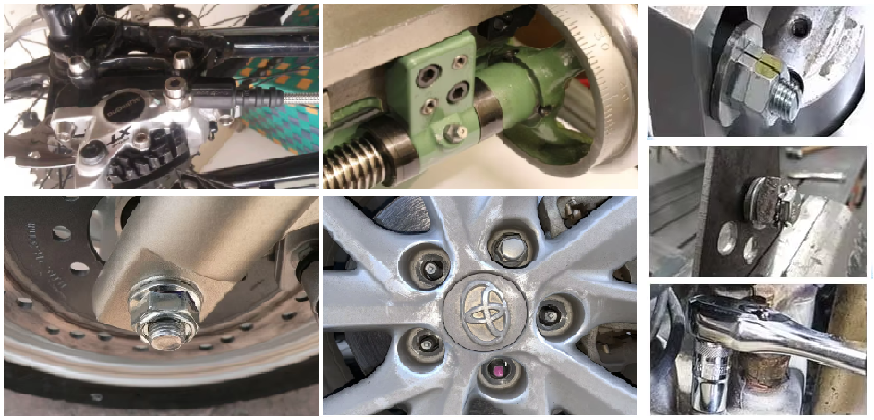

Product Application

Nuts are indispensable fasteners in countless industries, playing a critical role in securing components together with bolts or screws. Their diverse designs—from standard hex nuts to specialized lock nuts—make them adaptable to various environments, whether withstanding heavy loads, resisting vibration, or enabling easy adjustments.

Automotive industry: Used in engine assemblies, chassis, and body parts to secure components under constant vibration.

Construction sector: Essential in building frameworks, bridges, and scaffolding for stable structural connections.

Mechanical engineering: Integral to machinery, pumps, and motors, ensuring parts stay fixed during operation.

Electronics manufacturing: Employed in devices like computers and appliances to fasten casings and internal components.

Furniture production: Found in chairs, tables, and cabinets, often with T-nuts or barrel nuts for hidden, sturdy joints.

Aerospace and aviation: Used in aircraft structures and engines, where high-strength, corrosion-resistant nuts (e.g., titanium variants) are critical.

Marine engineering: Applied in ship hulls and equipment, with stainless steel or galvanized nuts to resist saltwater corrosion.

01

Footwear abrasion solutions

Lorem ipsum dolor, sit amet consectetur adipisicing elit. Explicabo exercitationem magnam velit iusto ratione, dicta, impedit excepturi nemo assumenda rem fugit tempore facere eum illum expedita ab deleniti sapiente. Porro.