8 10 12 14 16 Gauge Galvanized steel wire for building binding

description1

Production description

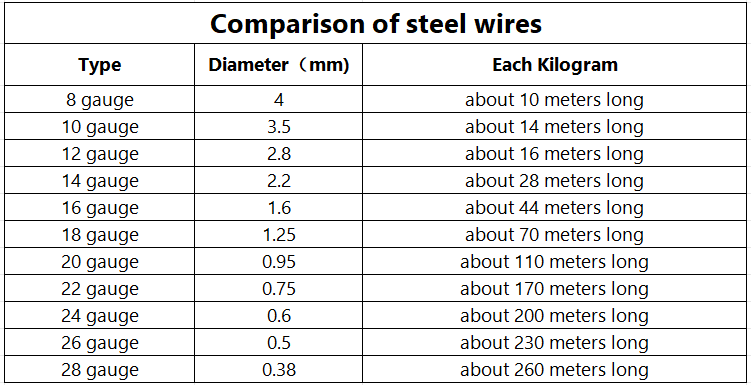

| Product name | Galvanized Steel Wire |

| Size | 0.15 - 5.0mm or customized |

| Zinc coat | 10 - 200g/m2 or customized |

| Wire weight | 5 - 50kgs/coil or customized |

| Grade | Q195, Q235B, 45#, 50Mn, 65Mn, 70Mn |

| Standard | ASTM, DIN, JIS, BS, GB/T, EN |

| Packing | Coil with plastic cloth inside and hessian outside or weave outside |

| MOQ | 5 tons |

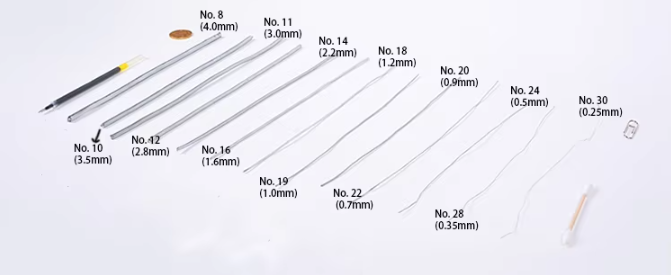

Galvanized wire has a wide range of specifications, mainly divided by wire diameter and thickness. Common specifications cover multiple ranges such as 0.8mm-6.0mm, and different specifications are suitable for different scenarios: fine galvanized wire with wire diameter of 0.8mm-1.2mm is soft and easy to bend, suitable for weaving handicrafts, fixing small potted plant branches, and tying lightweight daily items; The 1.5mm-2.5mm specification has moderate toughness and is commonly used for pulling agricultural fruit and vegetable vines and fixing garden flower shapes; 3.0mm-4.0mm medium thick galvanized wire has higher strength and can be used for temporary binding of building steel bars and packaging of stored goods; The 4.5mm-6.0mm thick galvanized wire has excellent tensile resistance and is commonly used in outdoor fence construction, fixing of large equipment components, and other scenarios, fully meeting the needs of different fields.

Production Application

01

Footwear abrasion solutions

Lorem ipsum dolor, sit amet consectetur adipisicing elit. Explicabo exercitationem magnam velit iusto ratione, dicta, impedit excepturi nemo assumenda rem fugit tempore facere eum illum expedita ab deleniti sapiente. Porro.

keywords:Galvanized Wire (Steel),Zinc-coated Steel Wire,Galvanized Steel Wire,High-tensile Galvanized Steel Wire,Electro-galvanized Steel Wire,Hot-dip Galvanized Steel Wire,Galvanized Carbon Steel Wire,Corrosion-resistant Galvanized Wire,Galvanized Binding Wire,Galvanized Steel Strand Wire